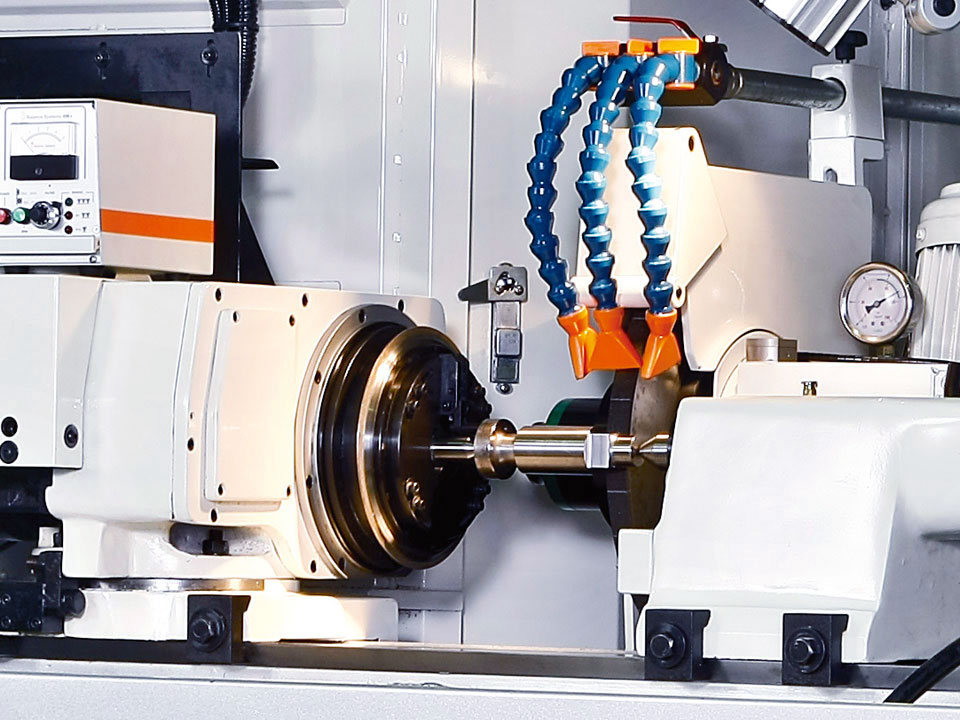

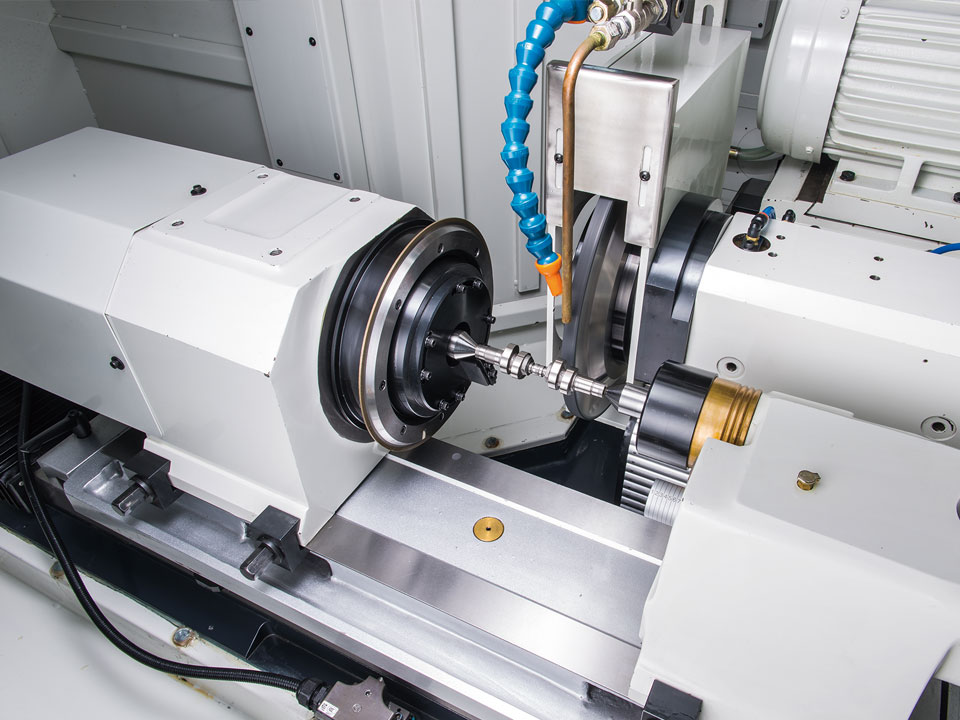

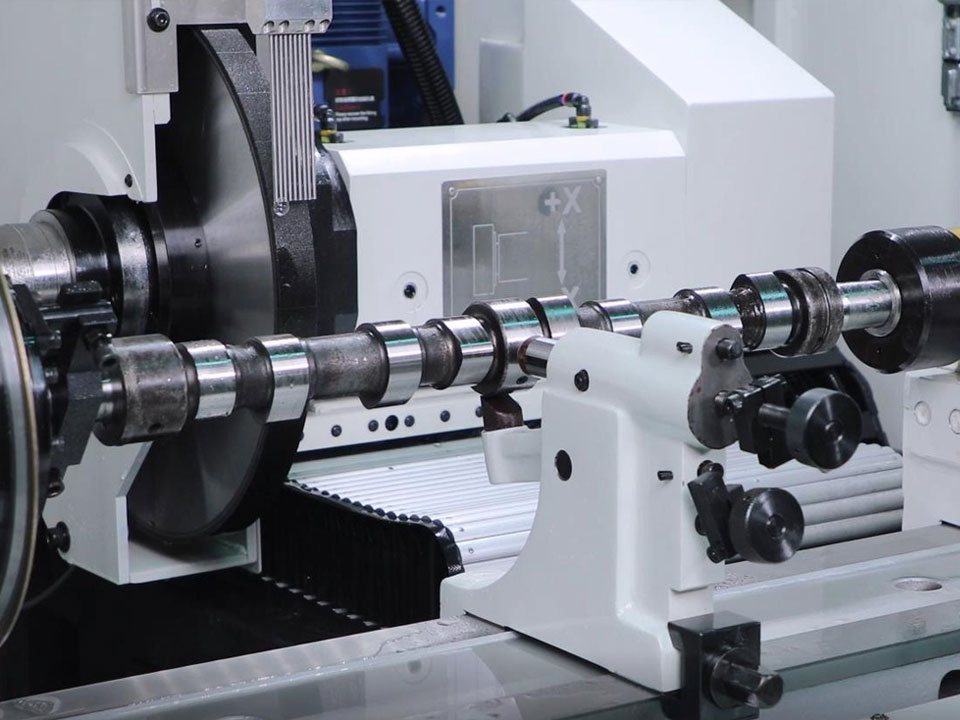

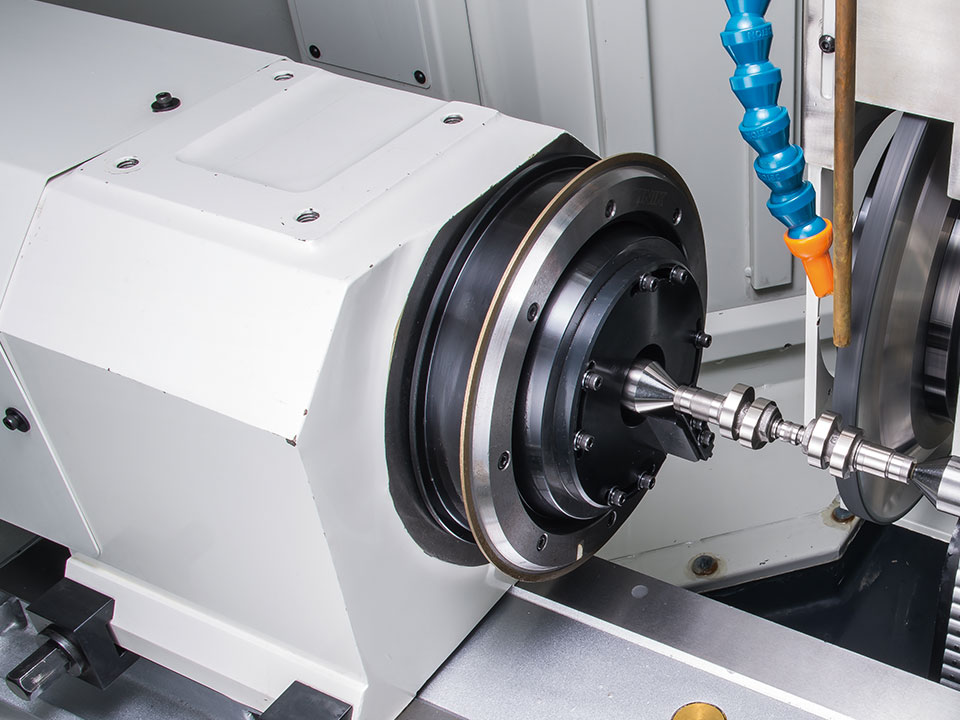

OCD-CAM

CNC Series

250 / 400 / 600 / 1000 mm

Distance between centers

Ø320 mm

Swivel over table

Ø300 mm

Max. external grinding dia.

For various eccentric circle or non-round shape workpieces grinding purpose, PALMARY develop CNC Cylindrical Grinder Cam Type for easily transfer from workpiece drawing to grinding program. The workhead could offer precise angle control due to the C axis has accurate angle encoder.