In accordance with the Occupational Safety and Health Act, an Occupational Safety and Health Committee is established, combining TQM (Total Quality Management) improvement initiatives. The committee holds regular monthly meetings, with the General Manager serving as the overall responsible person and senior executives acting as chairpersons. First-line supervisors, labor representatives, and safety officers from each department participate in the meetings. The committee reviews, coordinates, and provides recommendations on occupational safety and health practices and the implementation of the 6S methodology within the company's operations.

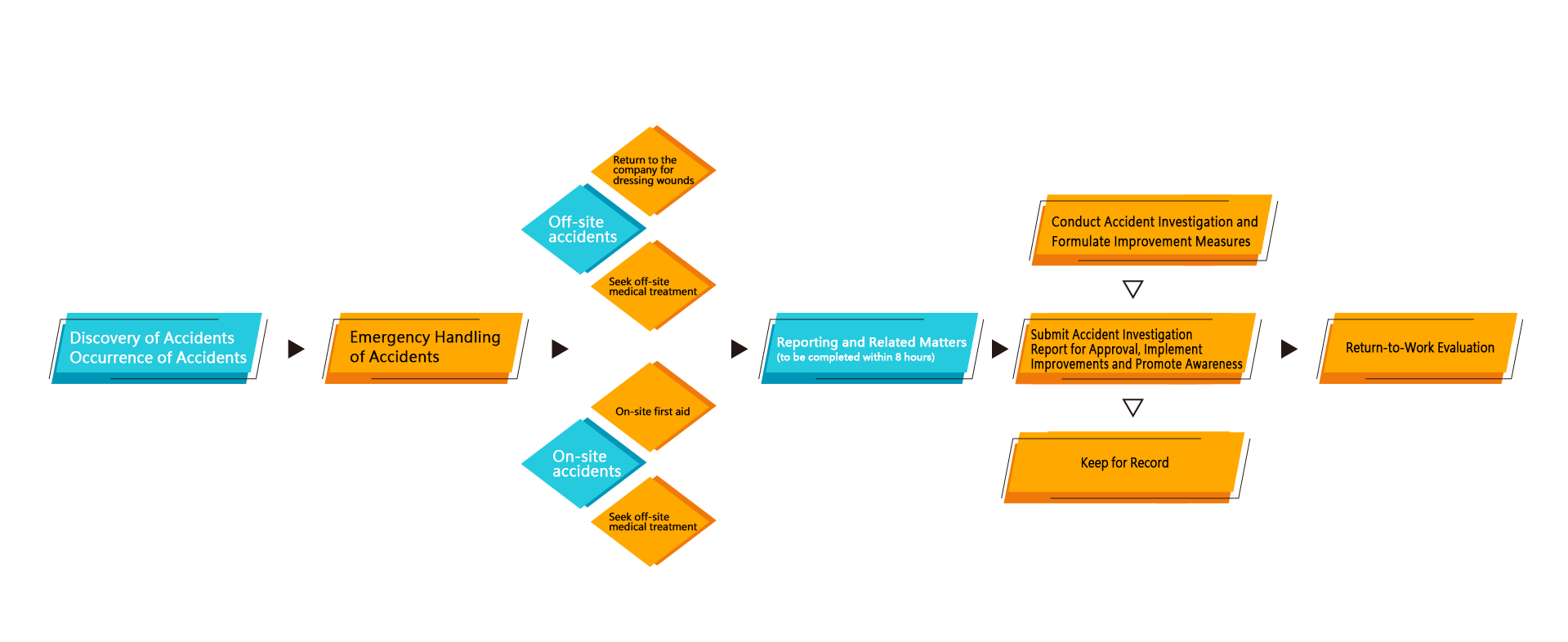

The Occupational Safety and Health Annual Plan includes at least 16 management objectives for tracking and management. It is jointly promoted by various departments, with related departments involved in planning and implementation. In addition, an internal/external accident and disaster notification procedure is established. Accident investigations cover the type of accident, direct and indirect causes, severity of the accident, follow-up improvement measures, and ongoing care and monitoring. This information serves as preventive measures and for resumption of work assessments.

Employees are encouraged to report potential occupational accidents or hazards through the "Suggestion Box" to enhance collective workplace safety and health management, making safety and health an essential element in everyone's work.

Badge of Accredited Healthy Workplace

Palmary machinery continually follows the health promotion and tobacco control policy. It has been proved to be qualified for accreditation-badge for a preliminary healthy workplace.

Education and Training

In addition to the basic new employee education and training, each department establishes occupational safety and health business supervisors, first aid personnel, and fire management personnel as required to maintain company safety and health. They are also required to stay updated with the latest occupational safety and health knowledge and assign personnel with relevant certifications to attend ongoing education and training sessions as required by law. To prevent various emergency situations, annual fire drills and emergency evacuation procedures are conducted to enhance the response capabilities of all personnel.

Environmental Safety Management

Palmary adheres to the regulations for industrial area management and wastewater treatment. Sewage is directly directed to the sewage treatment plant to meet government standards for discharge. Since 2013, environmentally friendly cleaning agents have been adopted in the manufacturing process to reduce environmental and personnel hazards. Filtering equipment that complies with regulations is installed for exhaust gas treatment to ensure compliance with legal requirements.

To continuously improve the work environment, environmental measurements are conducted every six months to monitor whether chemical and physical factors in the work environment comply with the legally permissible limits. If there are abnormalities in environmental monitoring, improvements or enhanced personal protective equipment are implemented, and cooperation with academia and industry is sought to improve human factors engineering hazards and prevent occupational accidents.

Work Safety Management

Palmary is dedicated to strengthening employee safety and health, aiming for zero accidents and preventing disasters. The company has a Occupational Safety and Health Office, with the General Manager serving as the overall convener. The 6S Safety Committee conducts regular and ad hoc inspections and reviews of the entire plant's working environment on a monthly basis to enhance employee awareness of work safety. To bridge the language and cultural differences among employees of different nationalities, safety signage production and public announcements are collected and translated by intermediaries, and responsibility managers in toolbox meetings disseminate the information to foreign colleagues.

All hazardous machinery and equipment within the company are registered and undergo regular maintenance as required by law. In addition, regular inspections are conducted in accordance with the ""Regulations for the Safety Inspection of Hazardous Machinery and Equipment"" to ensure the safe operation of machinery and equipment by employees.

Risk identification and updates are conducted for various plant operations, production capacity planning, response to contingencies, and abnormal incidents. After evaluation and discussion in Occupational Safety and Health meetings and management meetings, resolutions are made to ensure that all hazards are within controlled range, allowing employees to work with peace of mind in a safe environment.

Occupational Safety Education and Training Certificate Statistics Table

| Certificate | Public training for employees | In-house training for employees | Total qualified employees |

|---|---|---|---|

| Employer Supervisor | 3 | 0 | 3 |

| Occupational Safety Officer | 0 | 1 | 1 |

| Organic Solvent Supervisor | 1 | 0 | 1 |

| Fire Safety Manager | 1 | 0 | 1 |

| First Aid Personnel | 4 | 1 | 5 |

| Overhead Crane Operator | 22 | 2 | 24 |

| Forklift Operator | 10 | 1 | 11 |

Safety and Health Accident Handling and Investigation Process