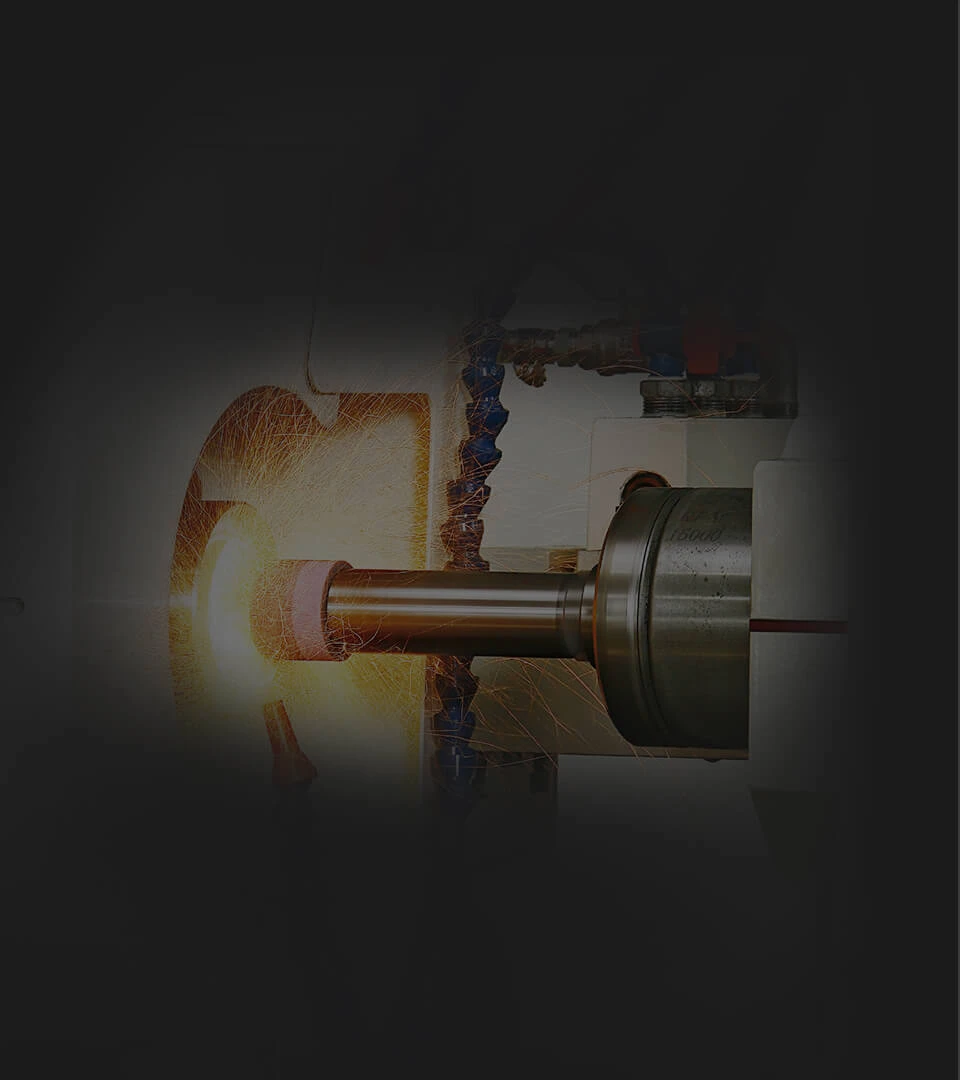

VERTICAL GRINDER

The CNC Vertical Grinding Machine is a high-performance, multi-function grinding solution. Its machine base adopts a honeycomb tubular and cross guideway structure, which greatly improves its rigidity and stability.

This CNC Vertical Grinder is also equipped with an ATC automatic tool change system, which can load up to 6 grinding wheels to correspond to different workpiece sizes and process requirements. The equipment also has the function of end face grinding; the main shaft of the grinding wheel can be rotated by 22.5 degrees, and the end face is ground with a bevel grinding wheel.

In addition, the waterproof sheet metal on the machine base can separate the coolant from the base, which not only reduces thermal deformation that may affect dimensional accuracy, but also prevents dirt from entering the machine base, ensuring reliable operation of the equipment.

For large workpieces or those difficult to clamp, the CNC Vertical Grinder can easily solve these challenges. With the processing versatility of the ATC automatic tool change system, inner diameter, outer diameter, and end face grinding can all be completed in one clamping process.

This integrated process helps ensure geometric accuracy, including concentricity and squareness. Therefore, vertical grinding machines are widely used in various industries such as machinery, bearings, aerospace, gears, energy, ships, and molds.

As one of the leading Vertical Grinding Machine Manufacturers, PALMARY provides vertical grinders that meet high precision and high efficiency production demands across industries.

Welcome you to contact us for more information or to find the right CNC vertical grinding solution for your specific application.

Look For Machine From Your Industry

Go to Application