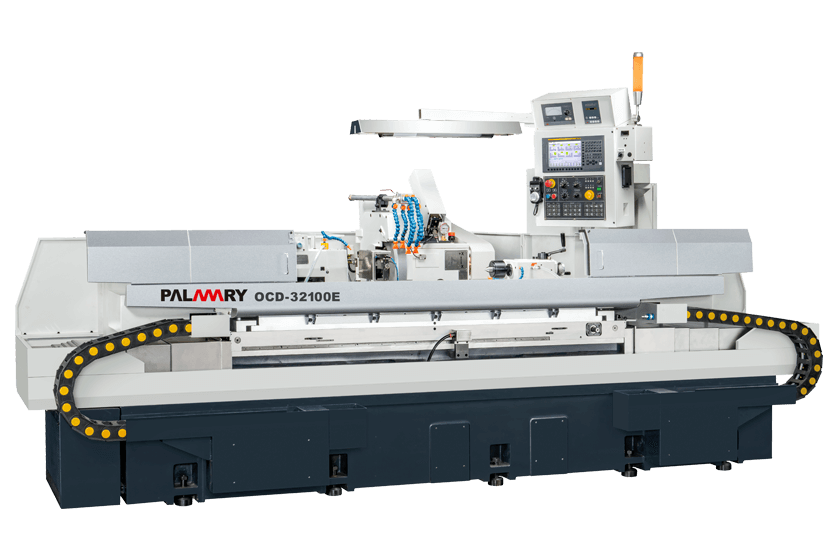

OCD-E

CNC Series for Spindle

1000 mm

Distance between centers

Ø320 mm

Swivel over table

Ø300 mm

Max. external grinding dia.

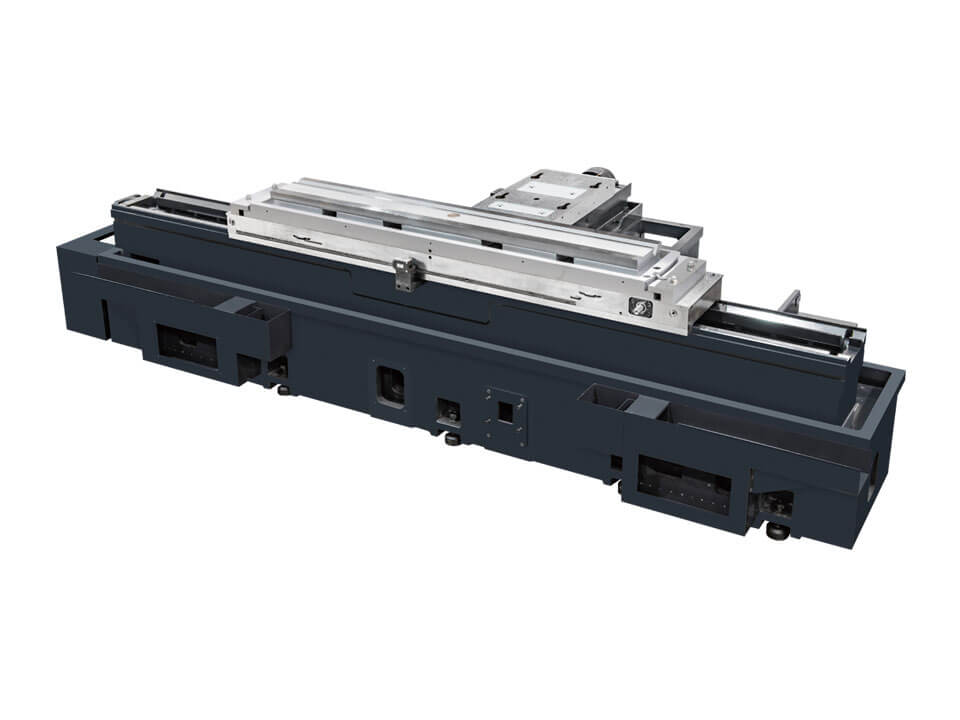

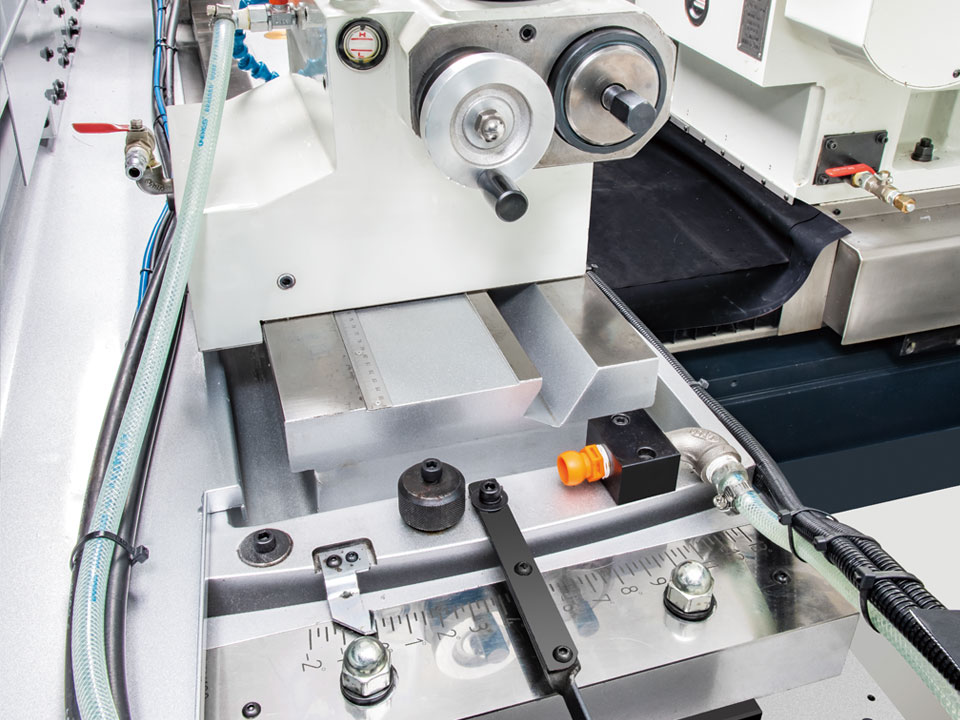

The machine structure is strengthened with same design of heavy duty cylindrical grinder. The enlarge hydrostatic wheel spindle construction could equip max. 125 mm width grinding wheel for plunge grinding application.