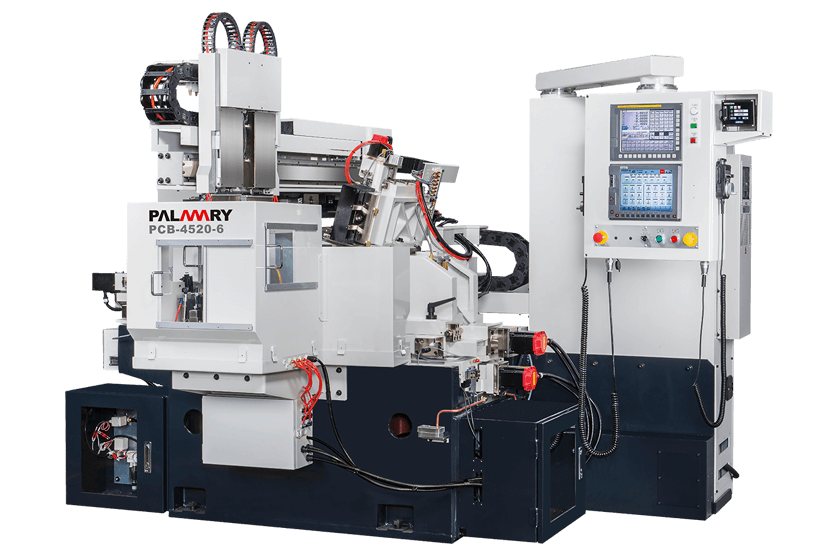

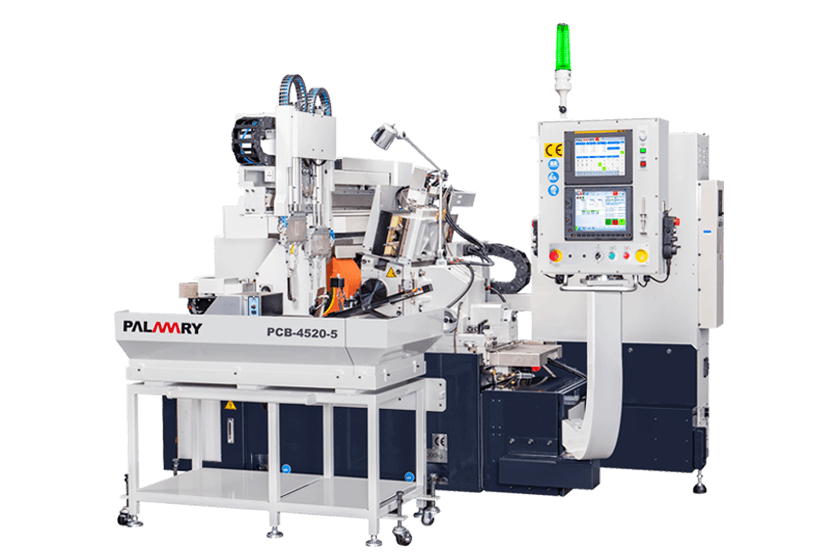

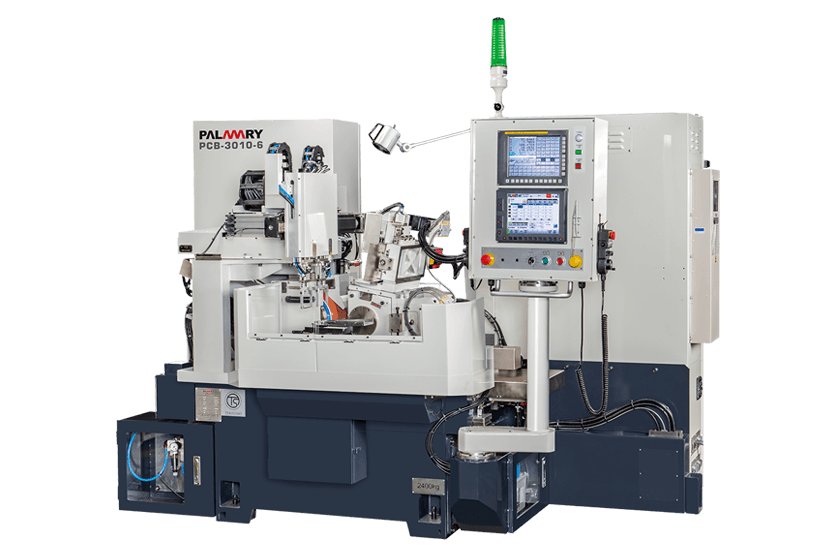

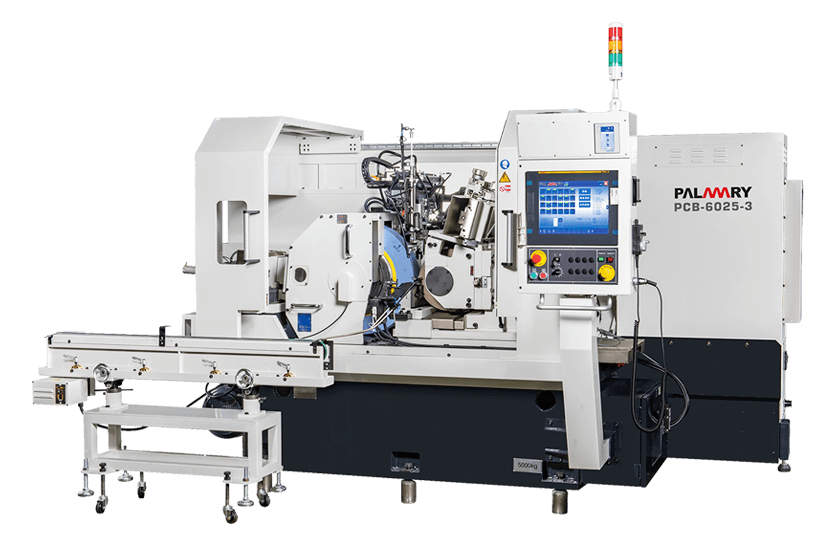

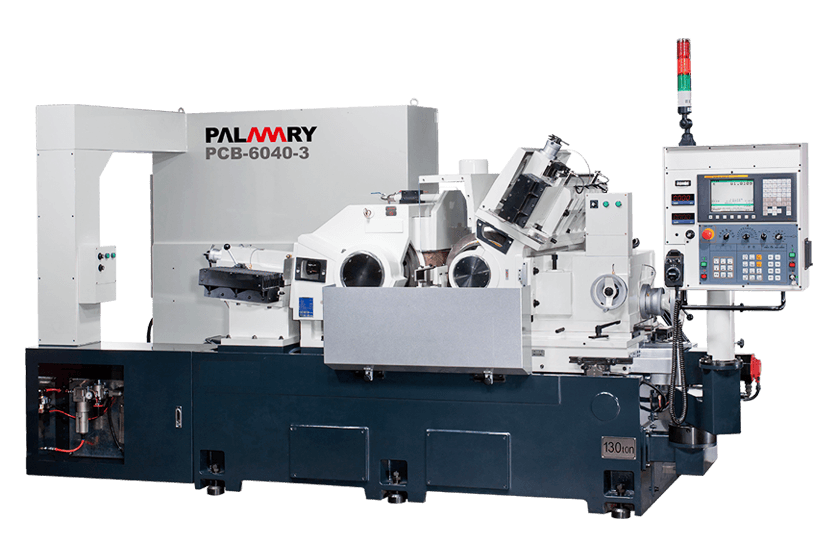

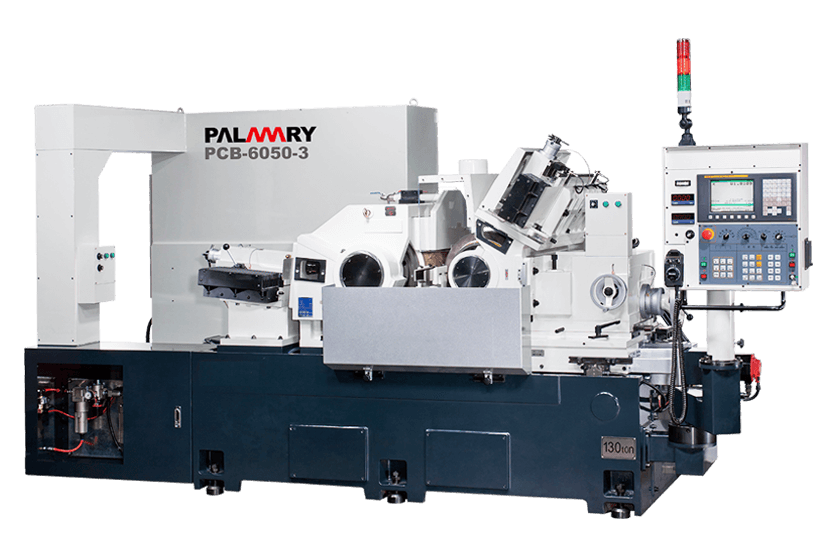

PCB

CNC Series

Dia. Ø1~80

Standard grinding range (mm)

Ø455 x 205/255 x Ø228.6

Grinding wheel size (mm)

Ø260 x 205/255 x Ø101.6

Regulating wheel size (mm)

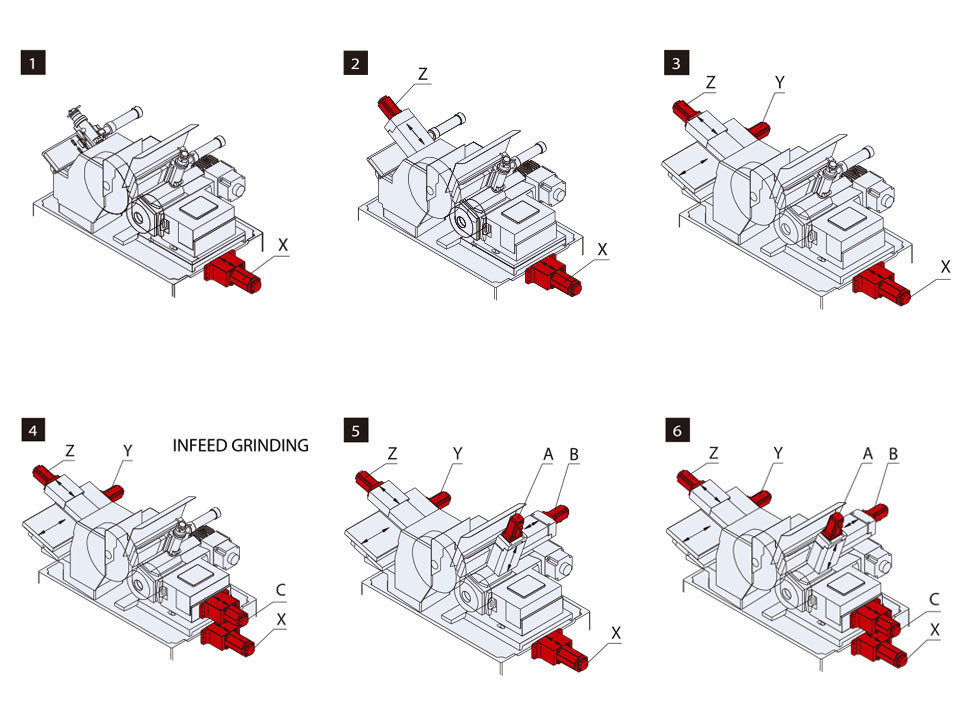

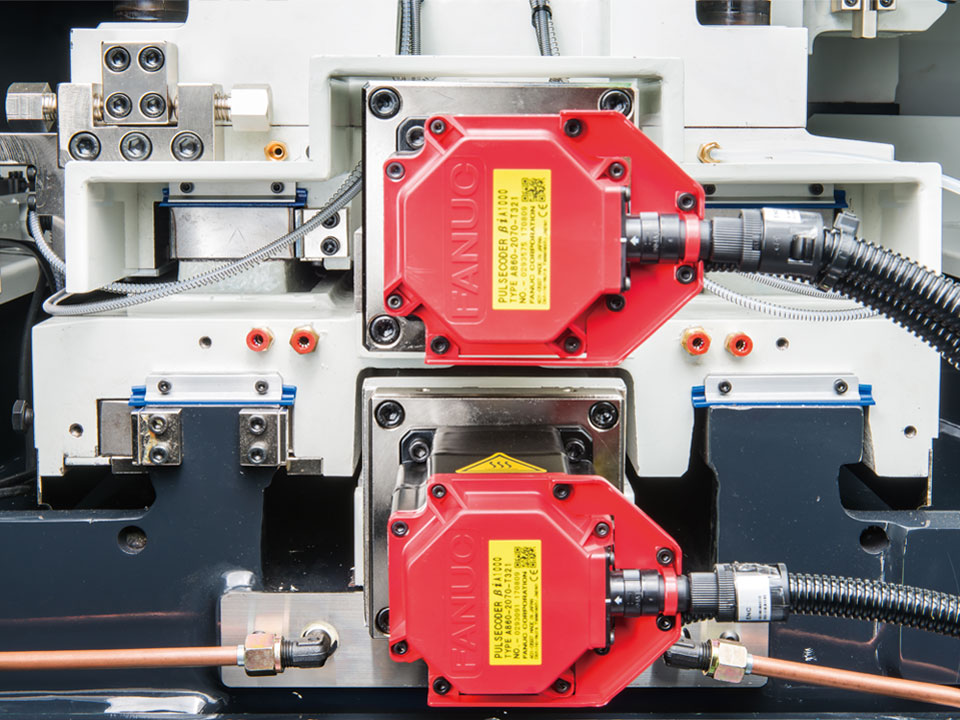

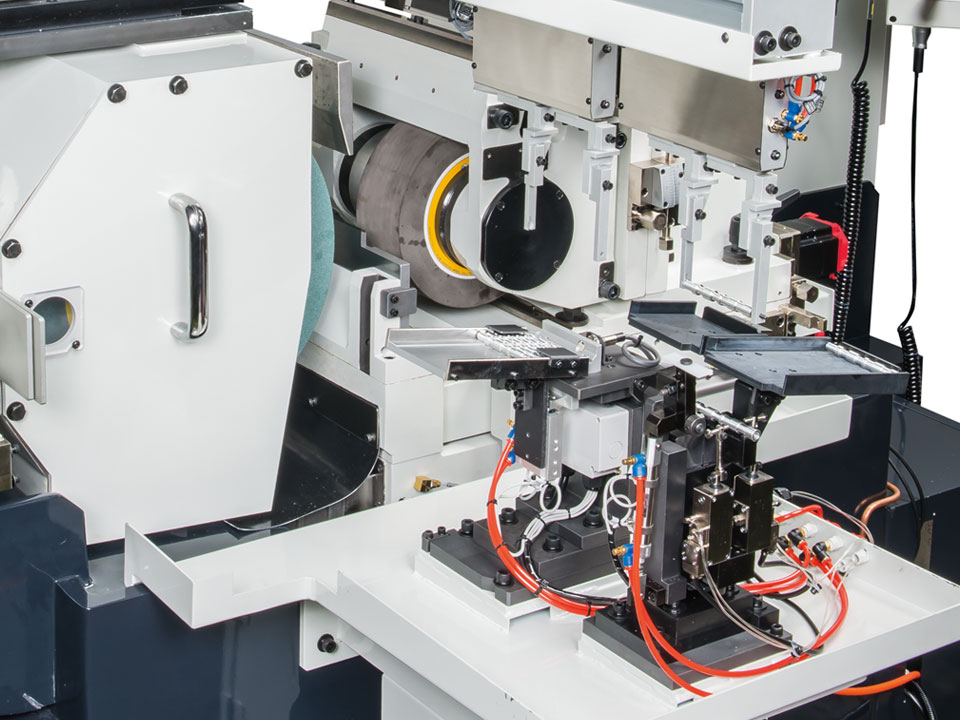

The CNC Series Bearing Type Spindle Centerless Grinders offer high rigidity and precision with multi-axis CNC control, driven by servo motors for convenience and accurate positioning. The use of high-accuracy NN bearings in the grinding wheel spindle ensures both precision and rigidity.

Compared to the FCL series, this Centerless Grinding Machine achieves a significant 26% energy saving, reducing production costs and environmental impact. CNC technology allows flexible and efficient operation, making it suitable for various industries like machining, mold manufacturing, and automotive, providing high-quality processing solutions.

Palmary's CNC Series Bearing Type Spindle Centerless Grinder combines CNC technology and Centerless Grinding Machines, delivering high performance, accuracy, and energy efficiency for an excellent processing experience.