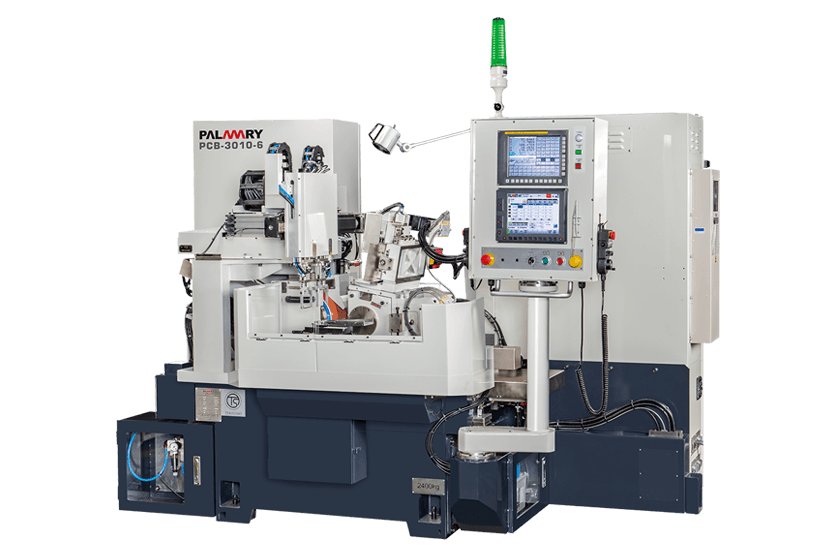

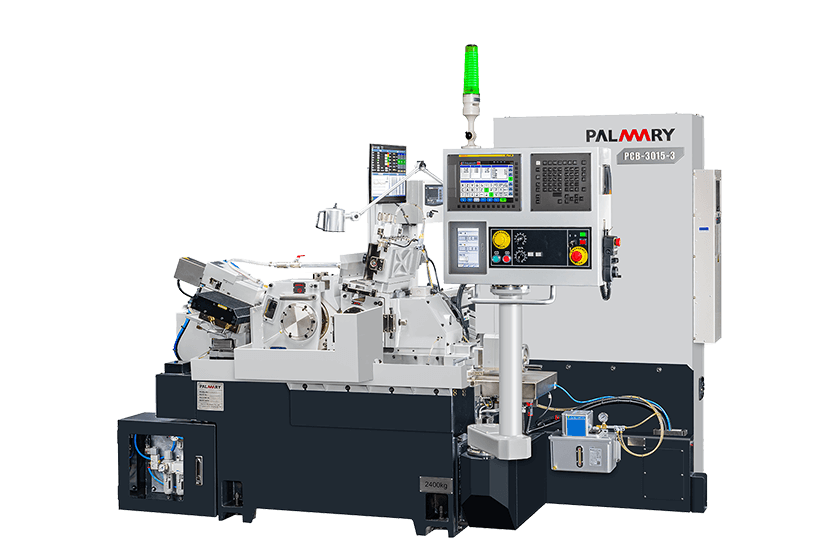

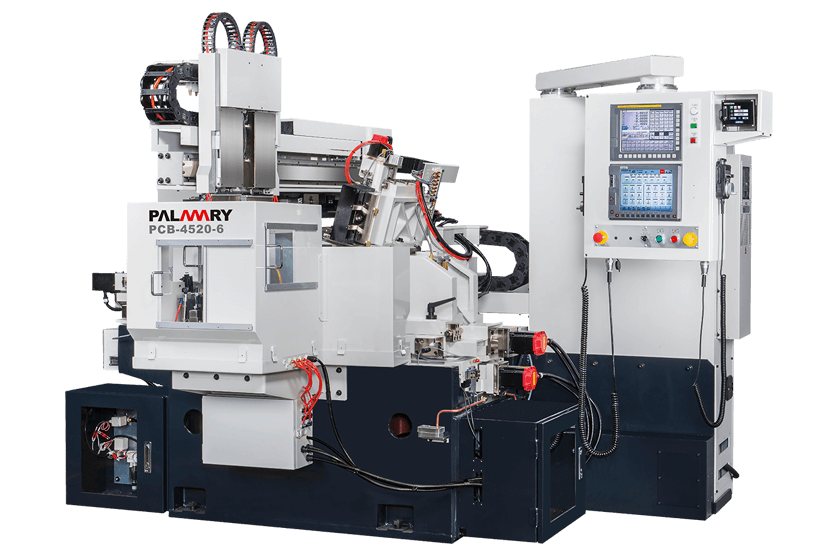

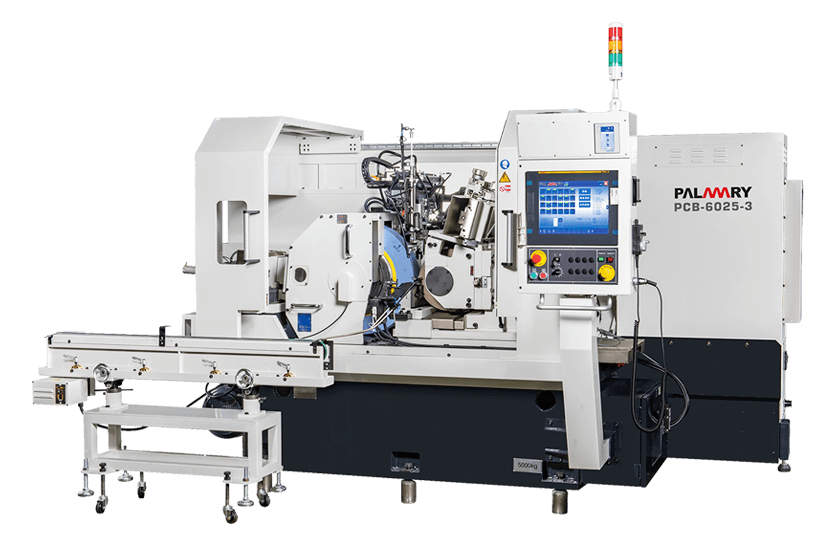

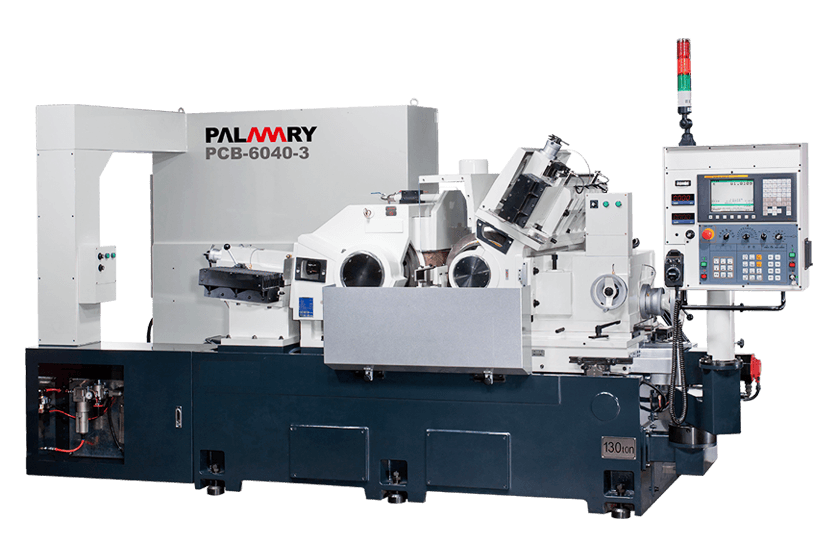

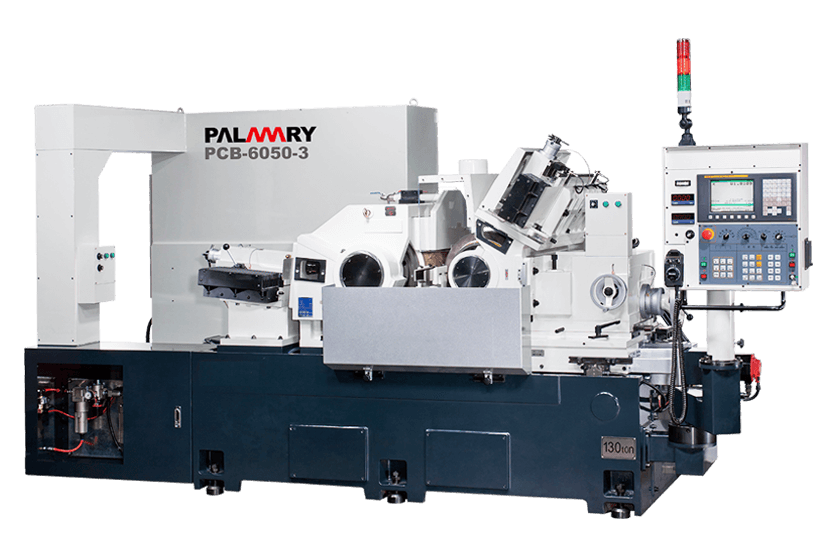

PCB

CNC Series

Dia. Ø0.3~25

Standard grinding range (mm)

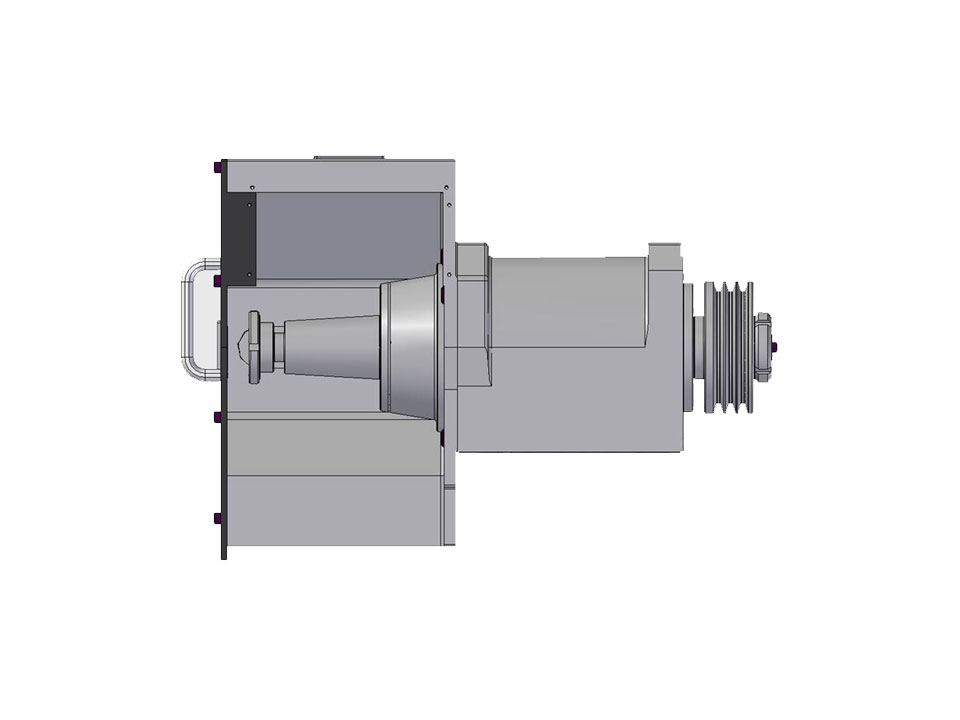

Ø305 x 100/150 x Ø177.8

Grinding wheel size (mm)

Ø205 x 100/150 x Ø90

Regulating wheel size (mm)

With a highly experienced design and manufacturing background in centerless grinders, PALMARY present the new bearing type CNC centerless grinder.

It is designed and engineered to offer the operational performance & higher accuracy you've come to expect.

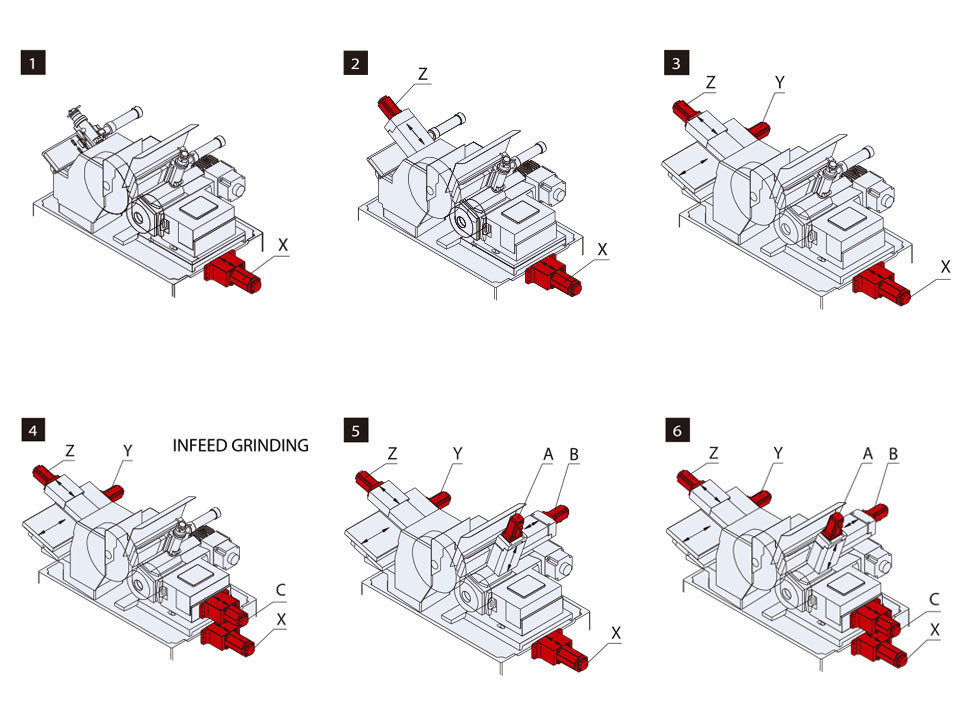

This 6-axis CNC centerless grinder could easily meet different grinding application. The unmanned production is possible with adding the auto loading and unloading system.