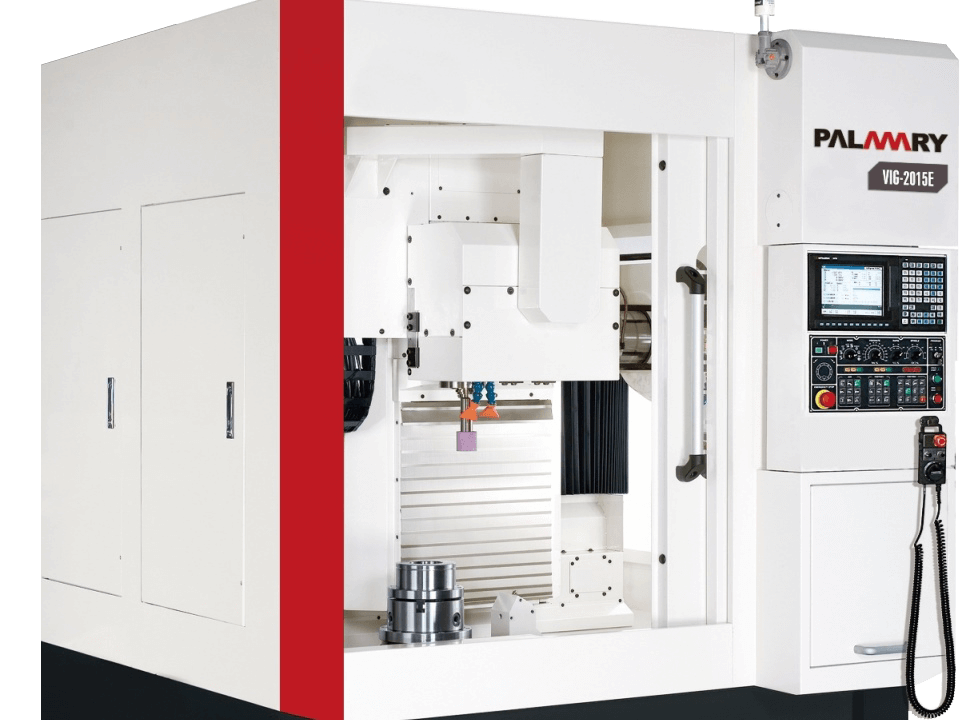

VIG

CNC Series

Ø200 mm

Chuck size

150 mm

Max. workpiece length

100 kgs

Max. workpiece load

VIG-2015/2015E is currently the smallest model in Palmary Vertical Grinding Machines, but it has excellent processing performance. The X and Y axes adopt the cross roller linear guide way, which has excellent load resistance. The design of the machine base adopts the honeycomb tubular and cross guide ways to provide a stable and reliable foundation. The operation interface adopts the graphic dialogue operation screen developed by Palmary itself, and the user can easily set various parameters.

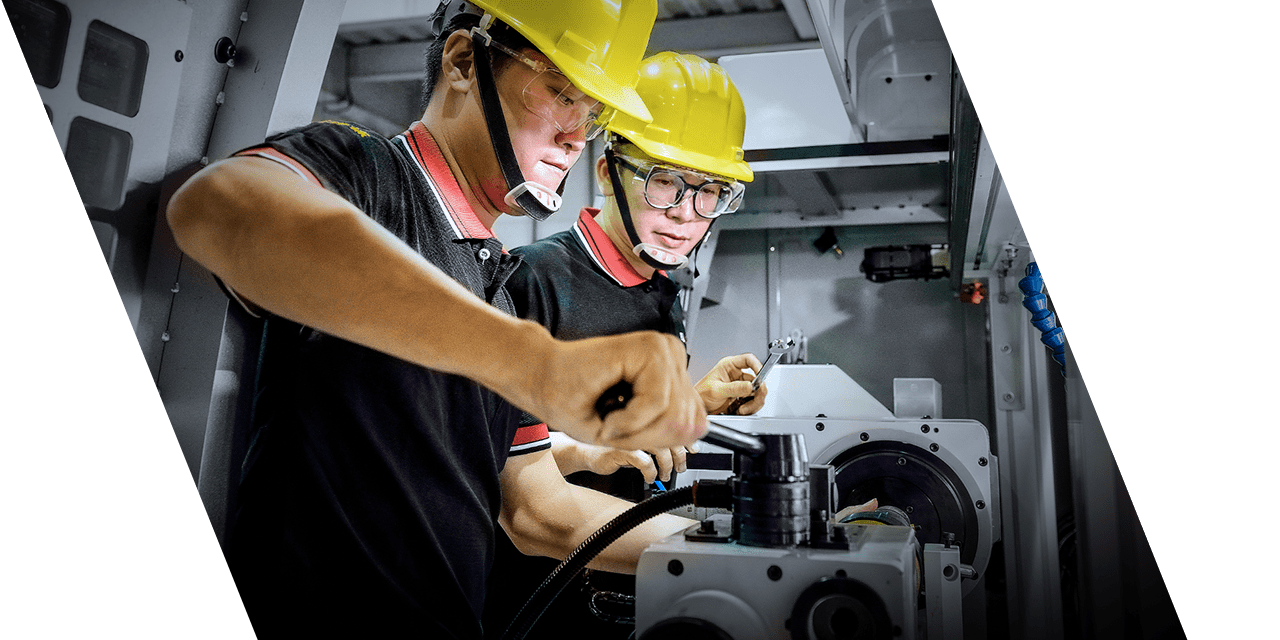

Vertical Grinding Machines are widely used in industries such as automotive, aerospace, mold making and metal processing…etc. We provide high-quality Vertical Grinding Machines to meet customers' needs for high-accuracy grinding and processing.