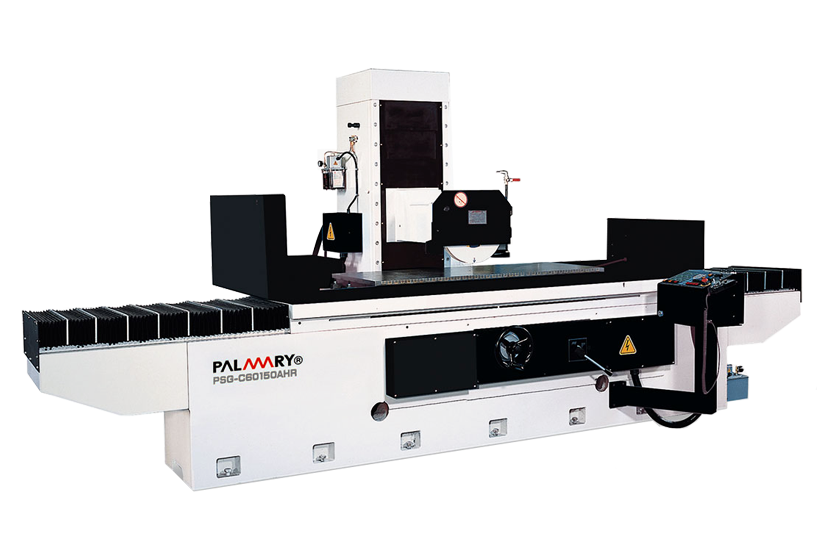

PSG-AHR

Hydraulic & NC Series

1500 mm

Working surface of table

600 mm

Max. distance center of spindle to table

405 x 50 x 127 mm

Wheel dimension

INTRODUCTION

The quality-proven surface grinder designed with accuracy and productivity in mind. It uses strong cast iron and excellent structural design which eliminates internal stress and ensures rigidity and stability.