OIG

NC Series

Ø6 ~ Ø70 mm

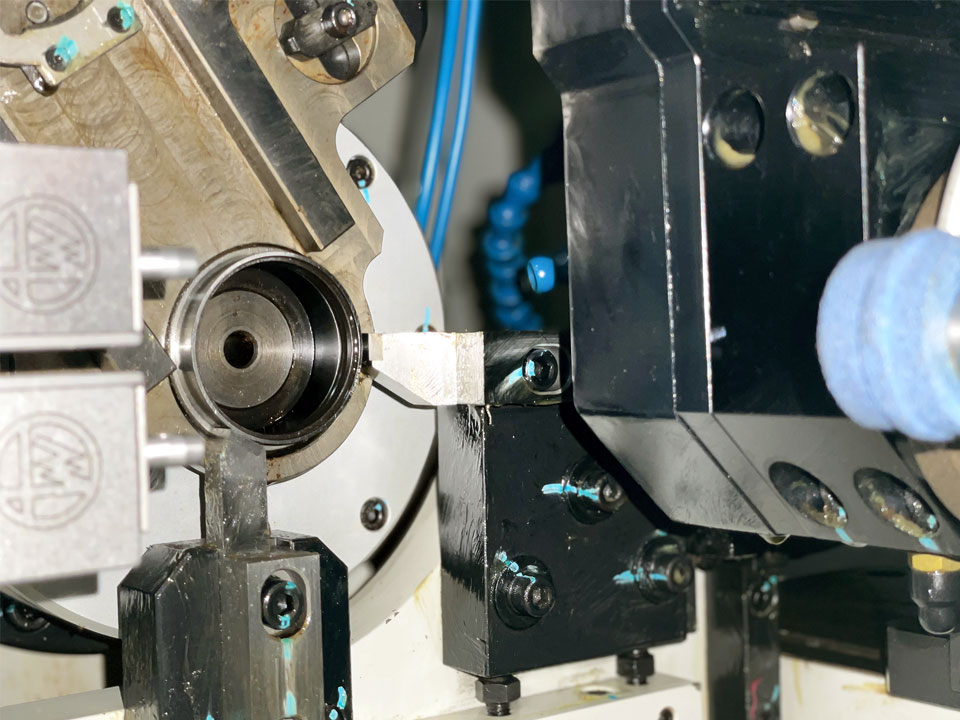

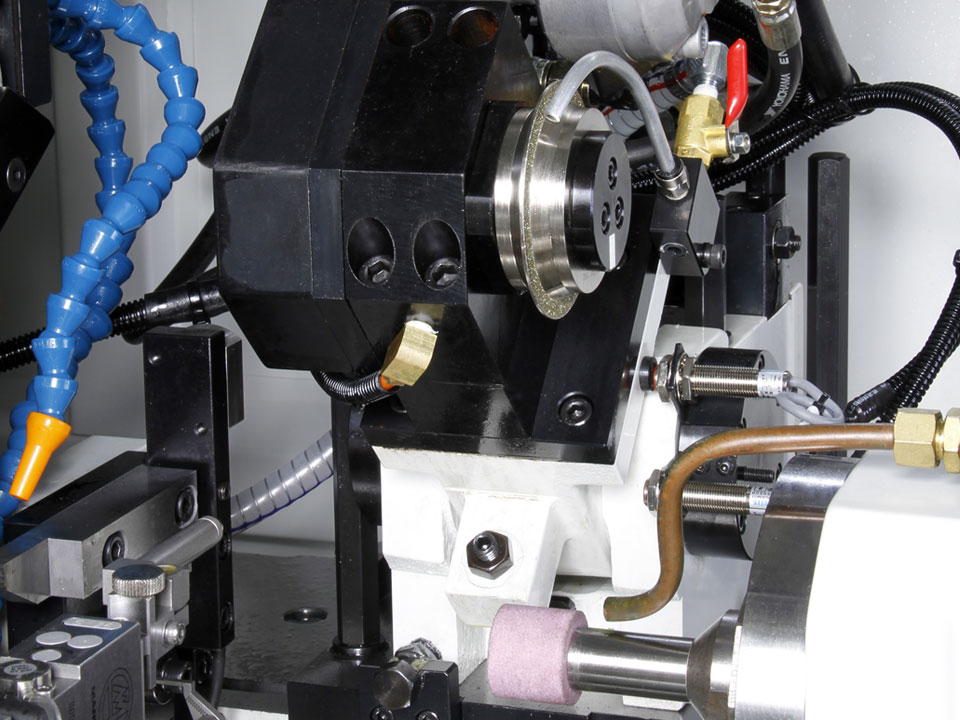

Internal grinding range

50 mm

Max. workpiece length

130 / 270 mm

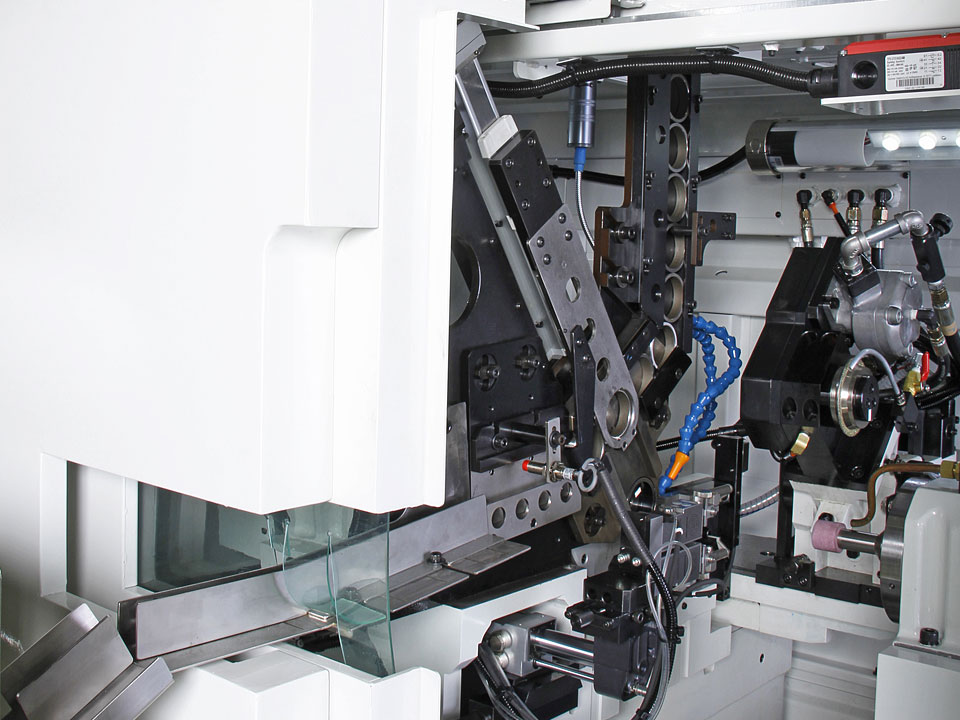

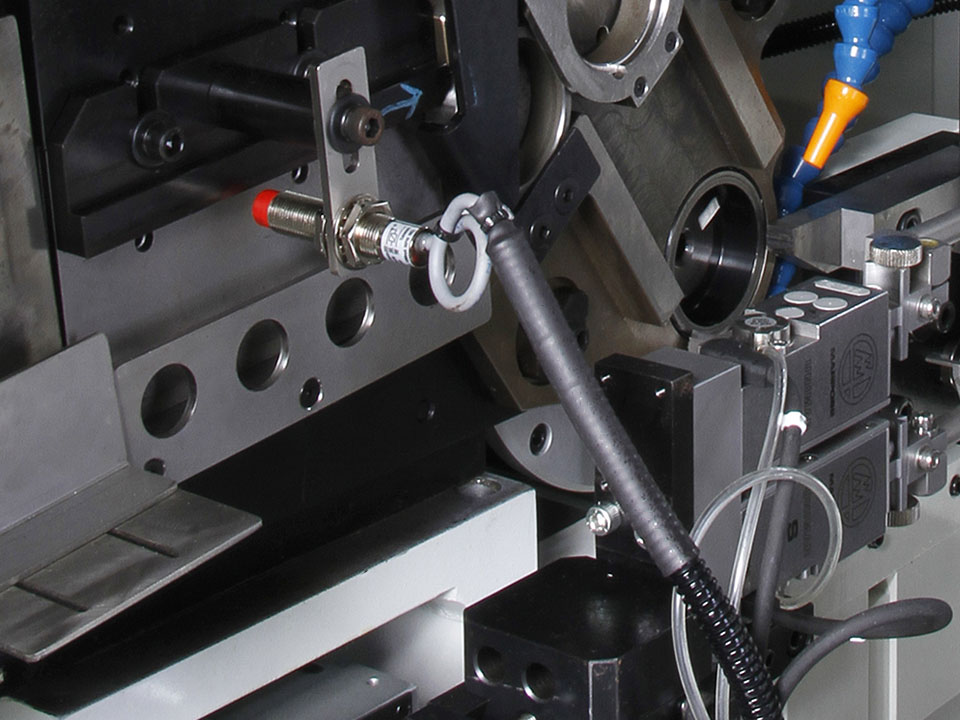

Max. table traverse ( X / Z )

The best grinding solution for the thin workpiece - Bearing inner diameter and inner groove grinding purpose.

With the best machine quality which similar to Japan-made but with more competitive price.

The internal grinder special model for bearing inner diameter & inner groove have the build-in type spincle to minimize the machine body size & floor space. The client could have the benefit of increasing factory space usage.