IG

NC Series

Ø150 mm

Internal grinding range

200 mm

Max. workpiece length

60 / 70 mm

Max. table traverse ( X / Z )

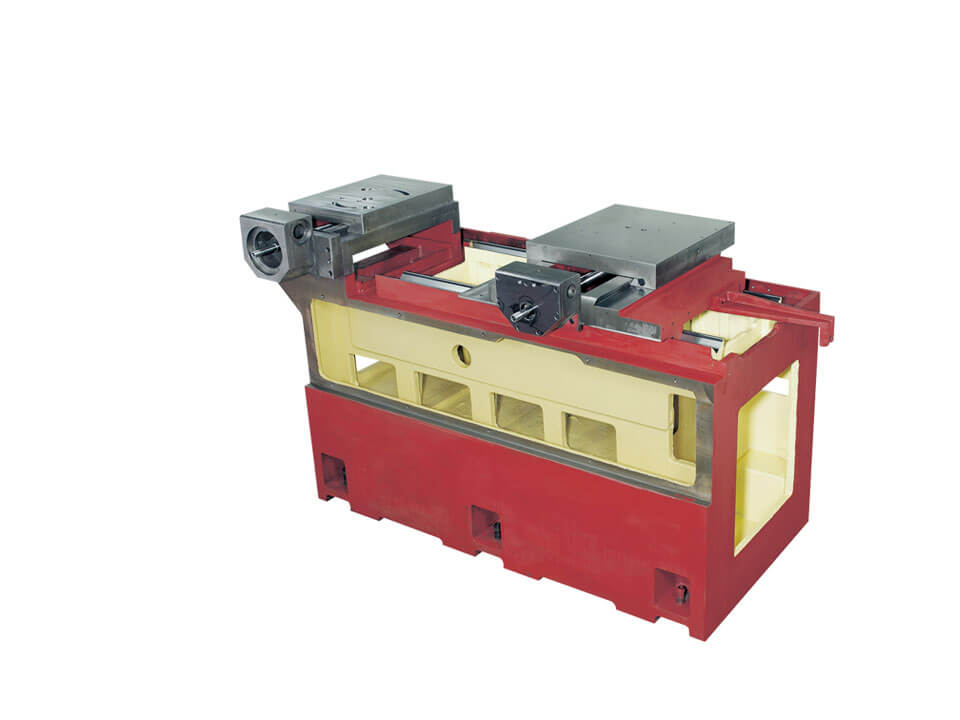

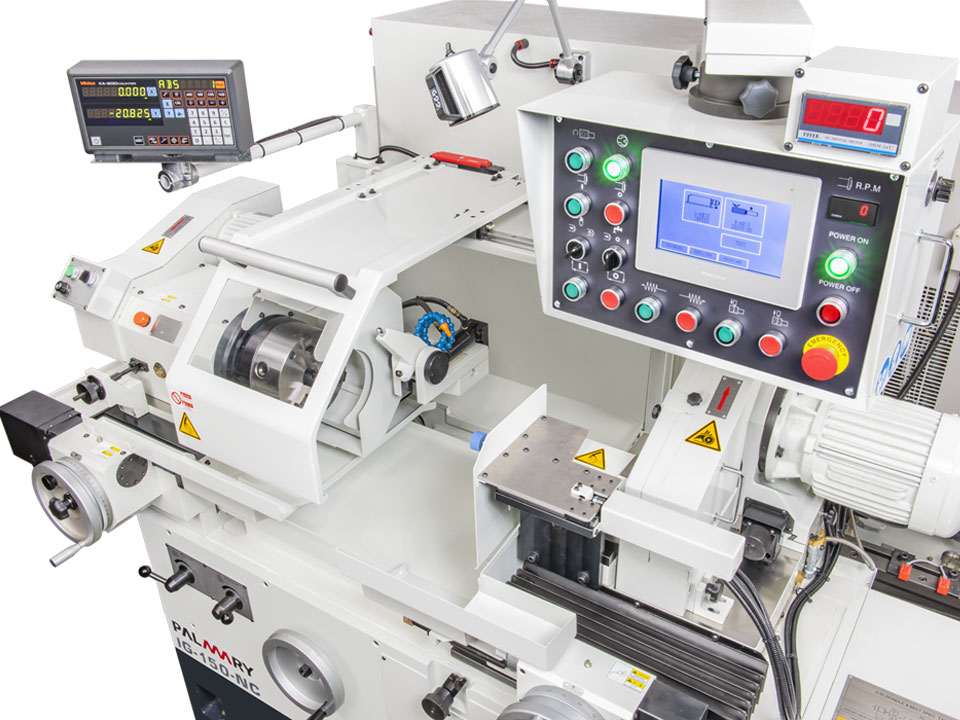

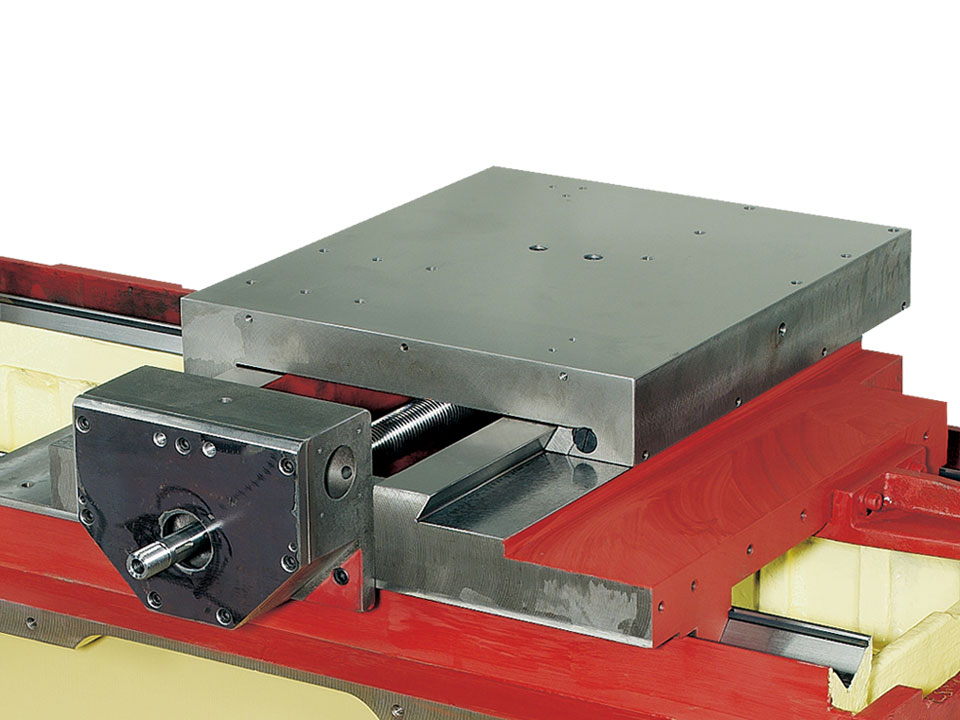

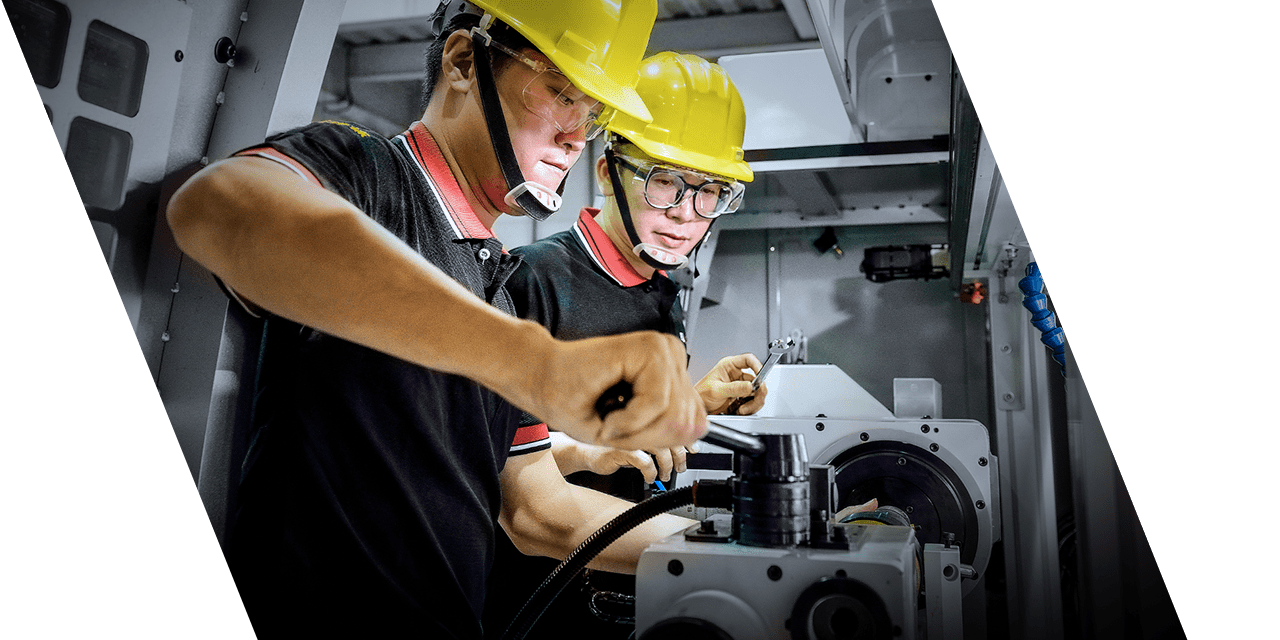

Internal Grinding Machine IG-150-NC / IG-150-2NC is an economical but efficient inner diameter Grinders with a conversational man-machine control interface, which makes the operation more intuitive. The feed axis of the equipment adopts precision ball screw and servo motor. The left and right sliding table of NC Series is driven by hydraulic. For 2NC Series, the left and right sliding table adopts ball screw and servo motor.

This NC inner diameter grinder has a wide range of applications and can be applied to grind various inner diameter surfaces, providing excellent accuracy and surface roughness. The NC Series can be used for internal diameter grinding of general through-hole parts, and the 2NC Series can be used for internal diameter grinding of workpieces with blind holes. They are commonly used in industries such as automobiles, molds, and components…etc.