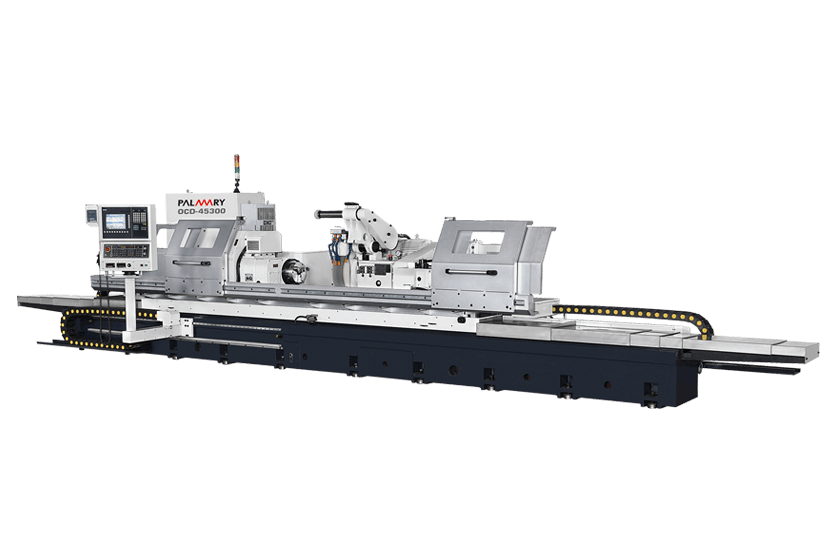

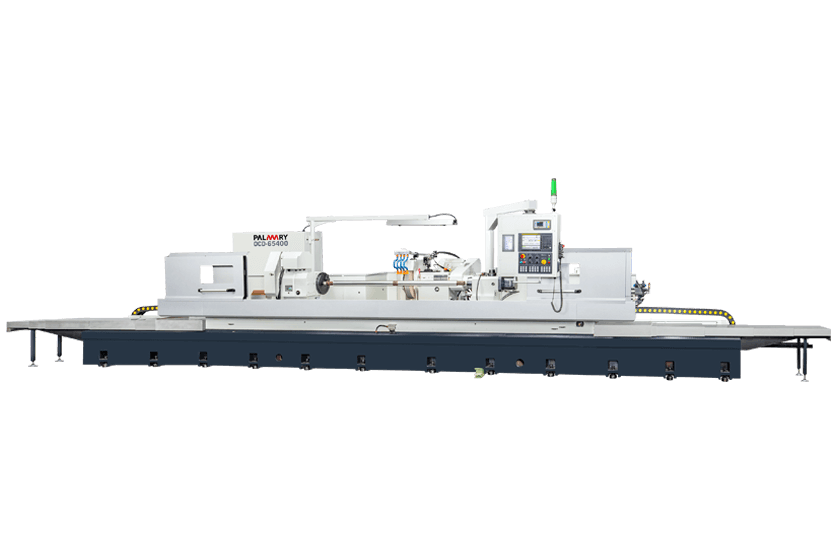

OCD Heavy Duty

CNC Series

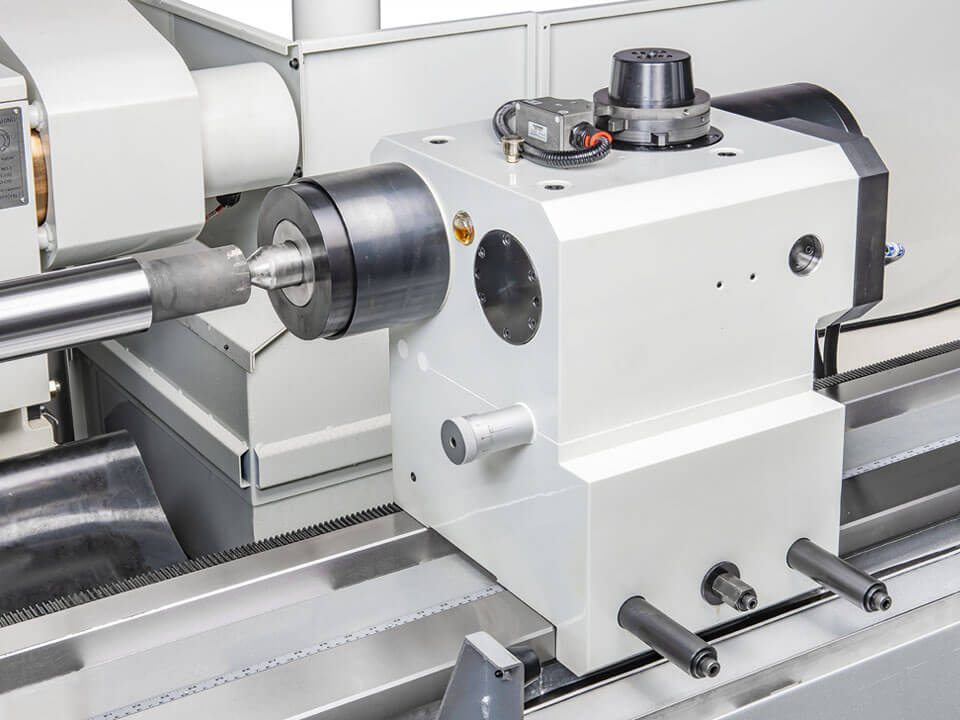

1500 / 2200 mm 3000 / 4000 mm

Distance between centers

Ø450 mm

Swivel over table

Ø420 mm

Max. external grinding dia.

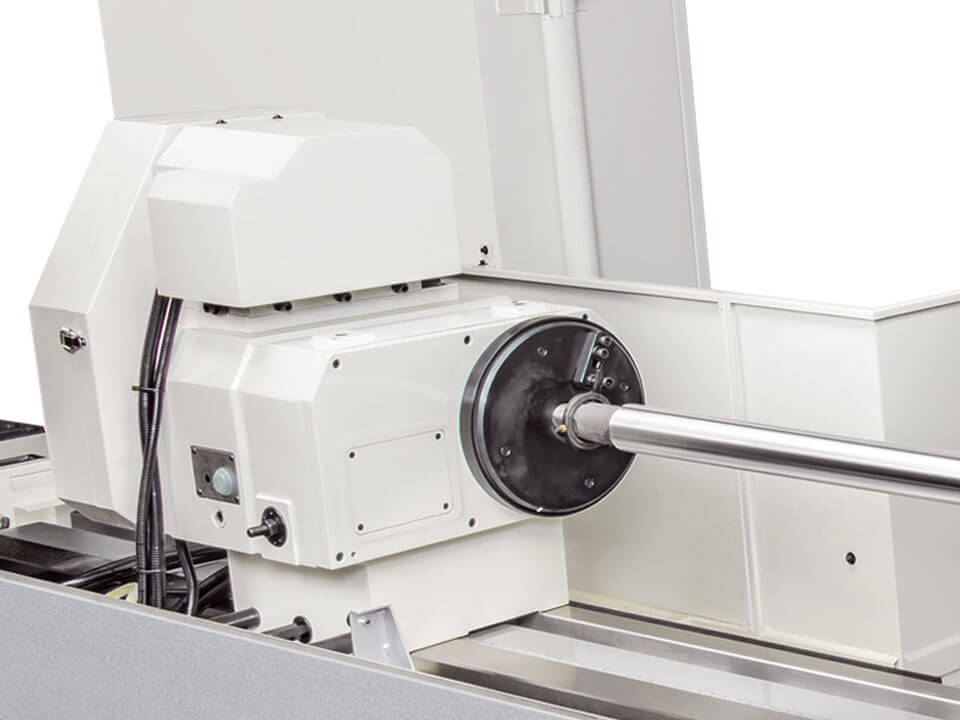

The external wheel is able to do formed O.D. grinding at once, in order to manage the total verticality and better the grinding efficiency.

APPLICATION:

Oversized gear shaft / Oversized printing shaft / Rolling shaft

Oversized motor shaft / Rubber rolling shaft / Oversized roller etc.