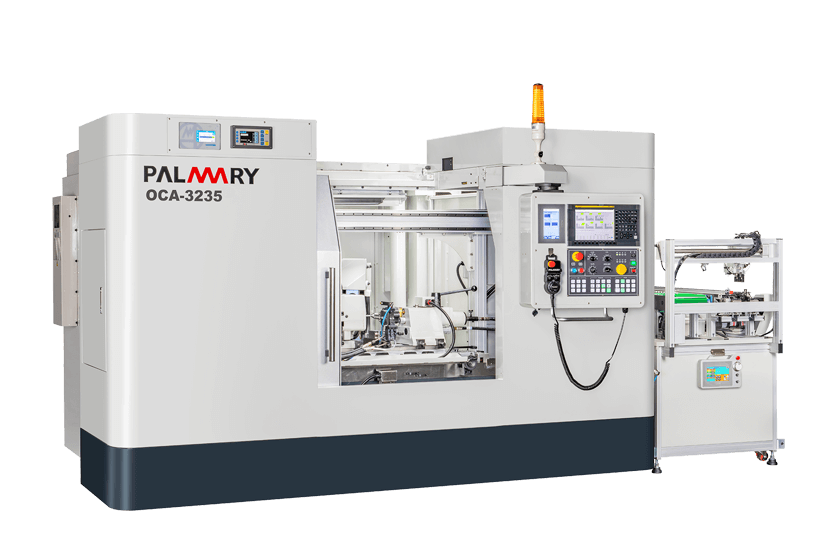

OCA

CNC Series

350 / 650 / 950 mm

Distance between centers

Ø320 mm

Swivel over table

Ø610 x 150 x Ø203.2 mm

G.W. size

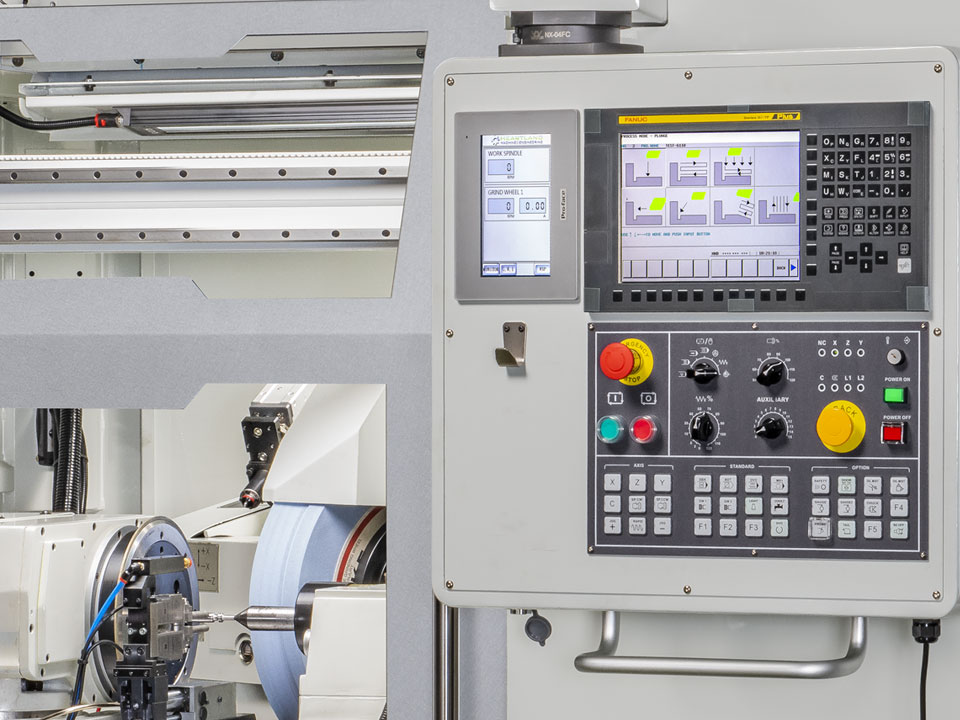

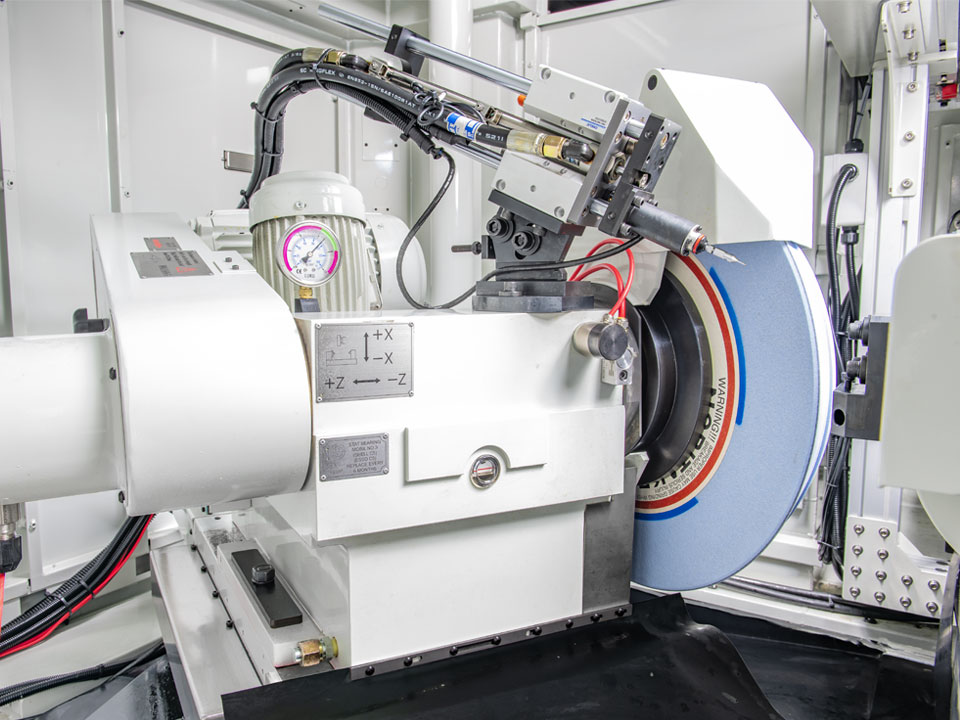

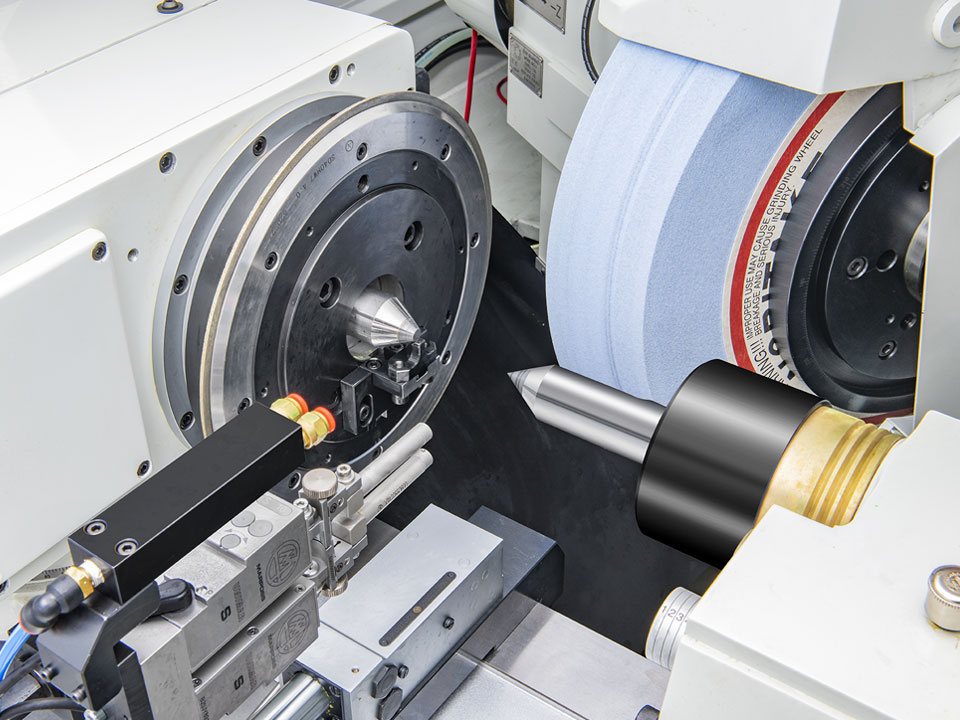

The CNC Cylindrical Grinder Angular Wheelhead (angular grinding) heavy duty type is designed with high efficiency, high accuracy and maximum operational convenience in mind.

The machine structure design fully meets ergonomic theorem for user-friendly operations. Rigid and stable construction, as well as a special wheel spindle design are combined with advanced CNC control to make cylindrical grinding easier and more accurate than ever before.