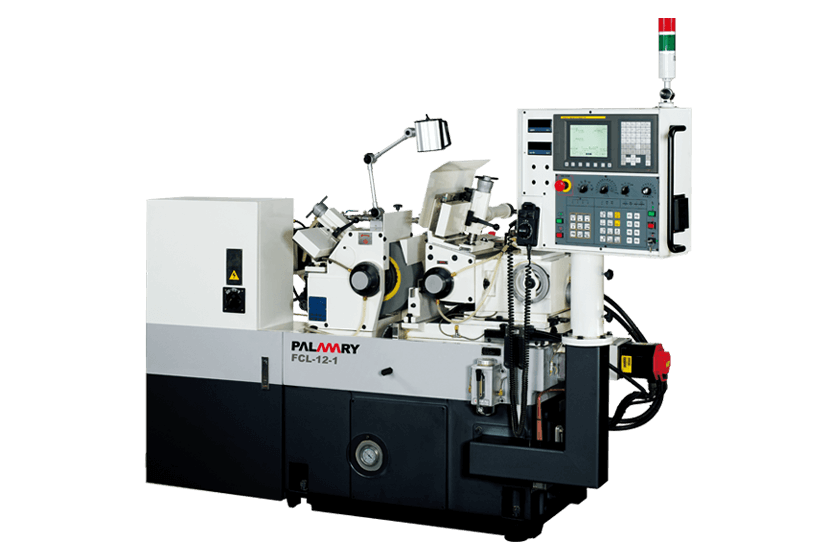

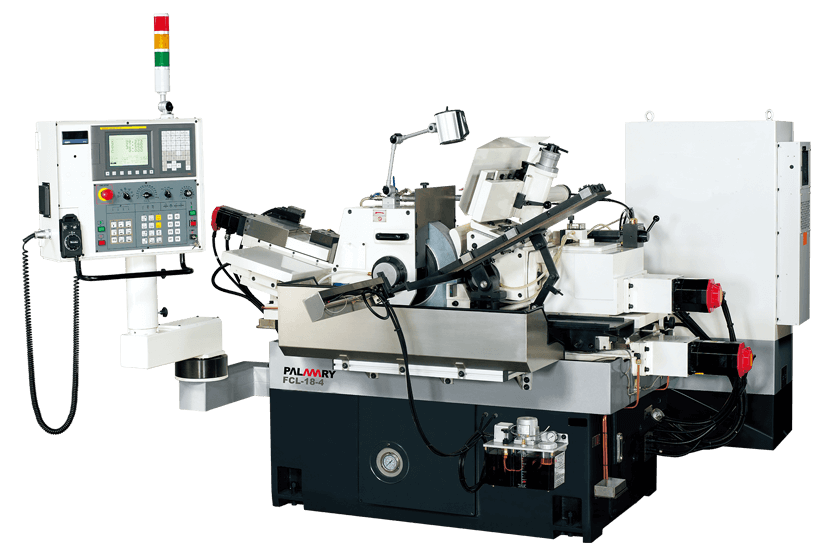

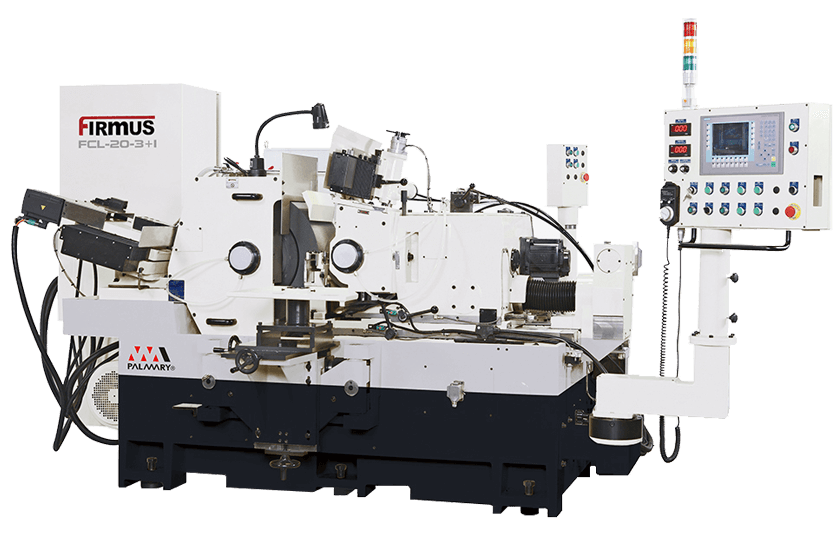

FCL

CNC Series

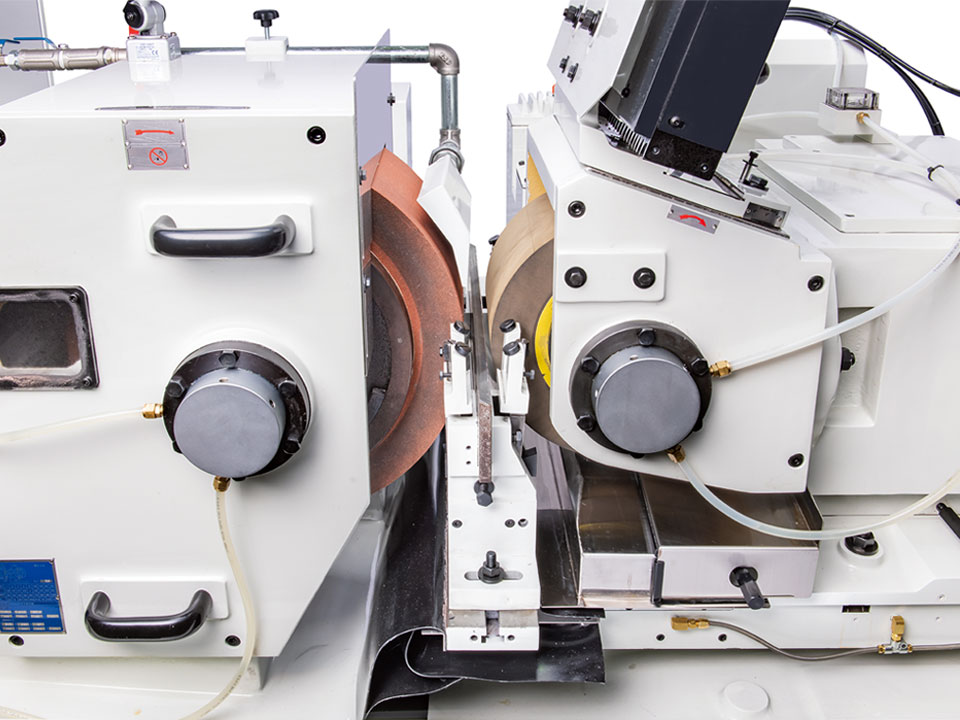

Dia. Ø1~40

Standard grinding range (mm)

Ø305 x 150 x Ø120

Grinding wheel size (mm)

Ø205 x 150 x Ø90

Regulating wheel size (mm)

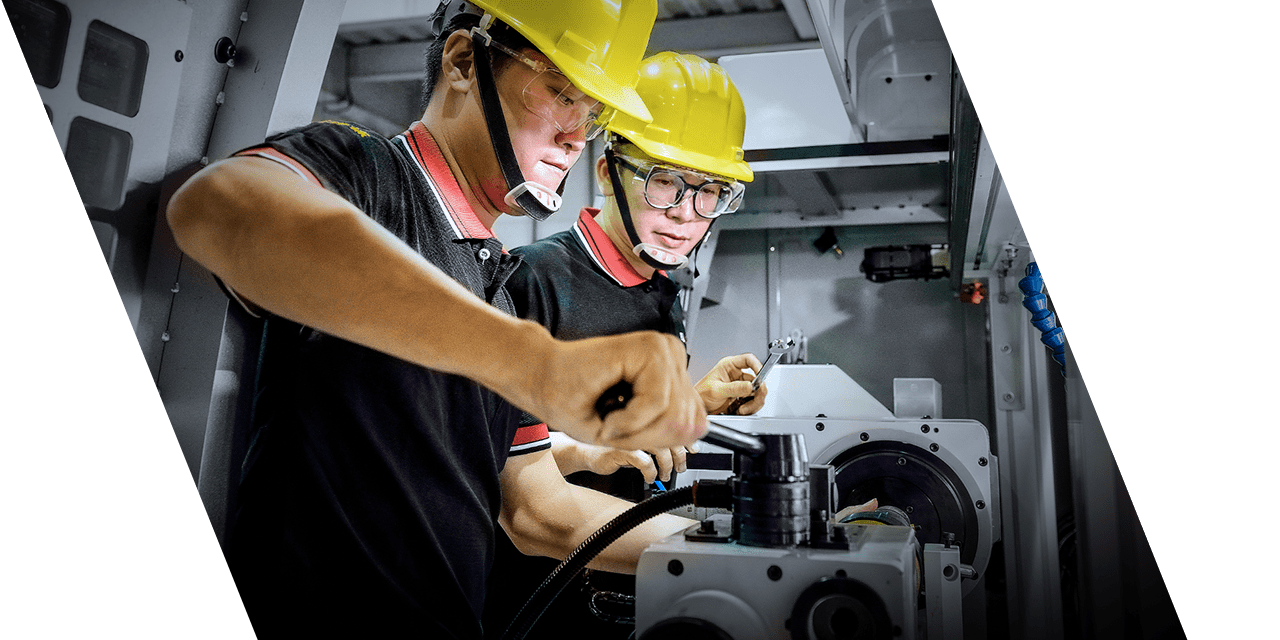

With a highly experienced design and manufacturing background in centerless grinders, PALMARY present a new series of CNC centerless grinder. It is designed and engineered to offer the operational performance you've come to expect.

Equipped with an advanced CNC control, featuring operator-friendly operation with maximum control convenience. When you require a machine that will greatly upgrade production efficiency and create more profits, PALMARY's new CNC centerless grinder will fully meet your requirements.