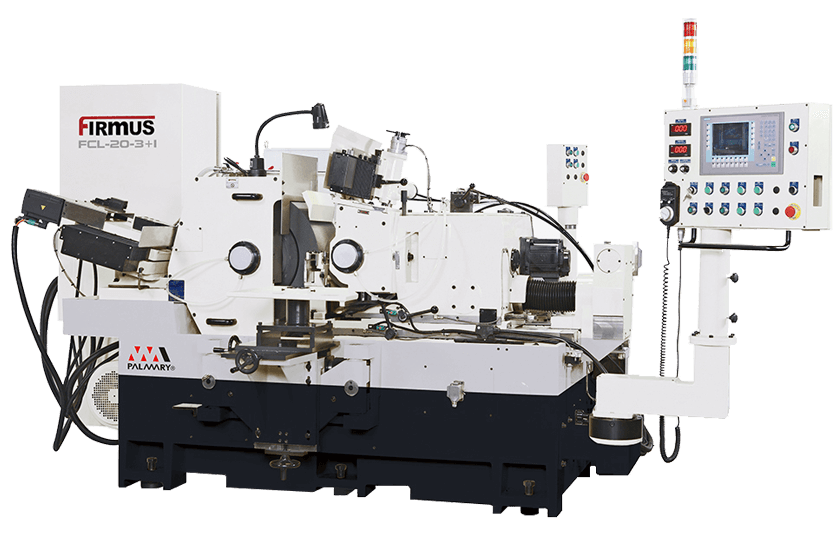

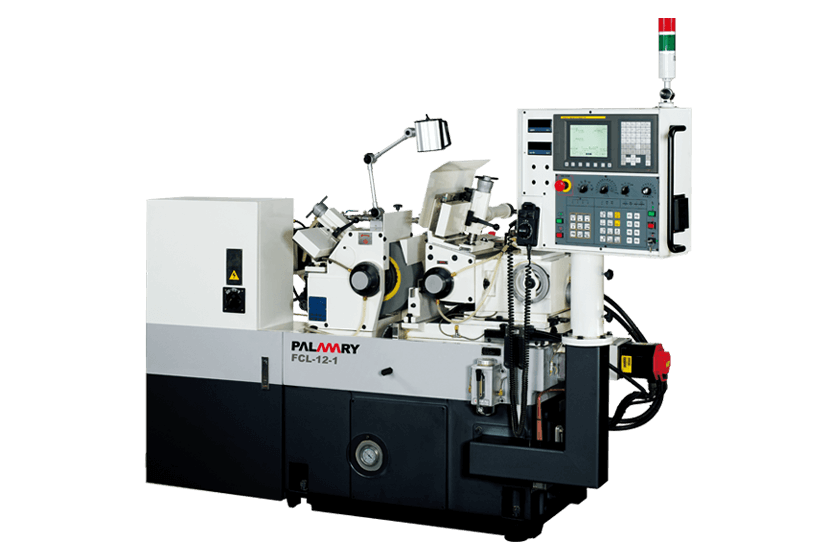

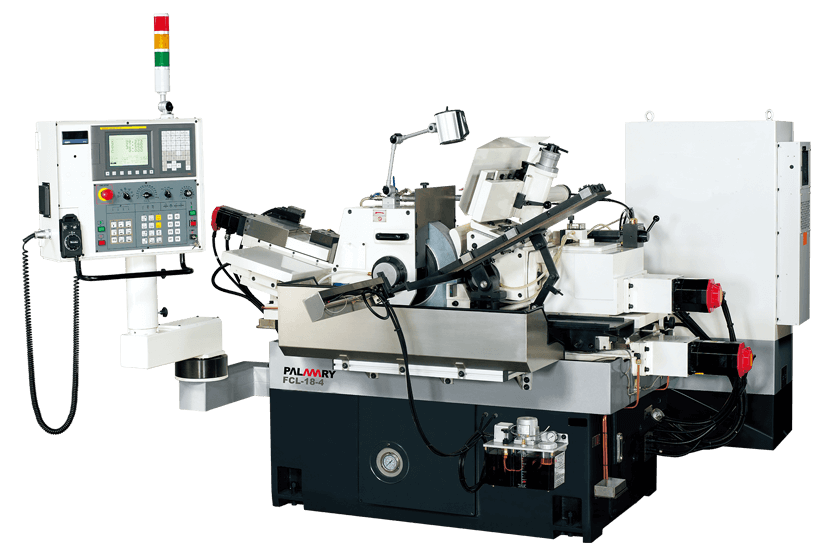

FCL

CNC Series

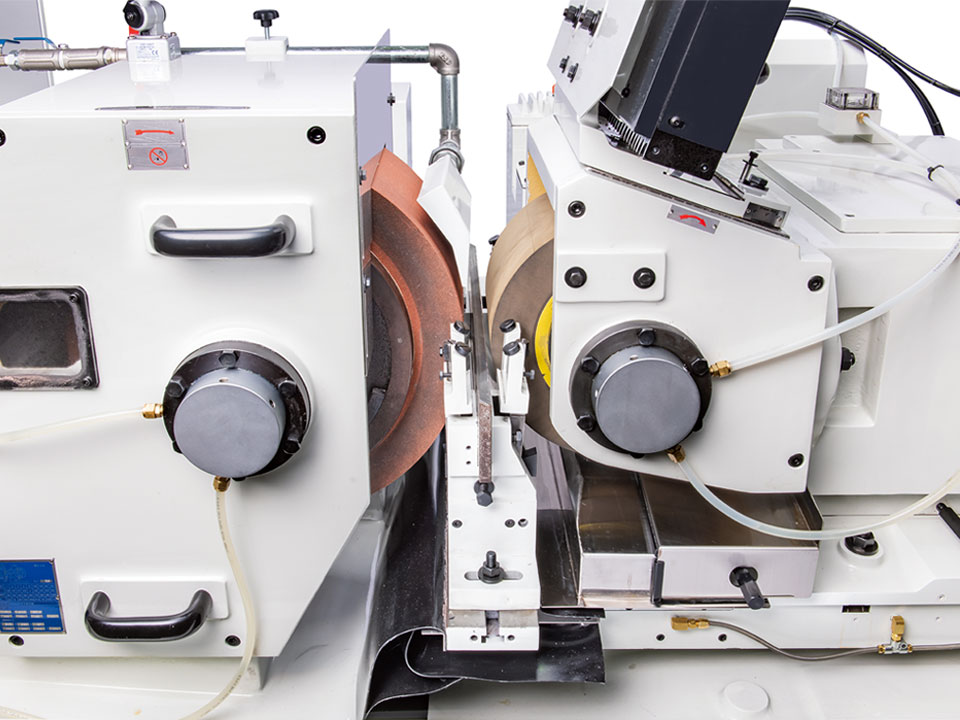

Dia. Ø1~60

Standard grinding range (mm)

Ø510 x 205 x Ø304.8

Grinding wheel size (mm)

Ø305 x 205 x Ø127

Regulating wheel size (mm)

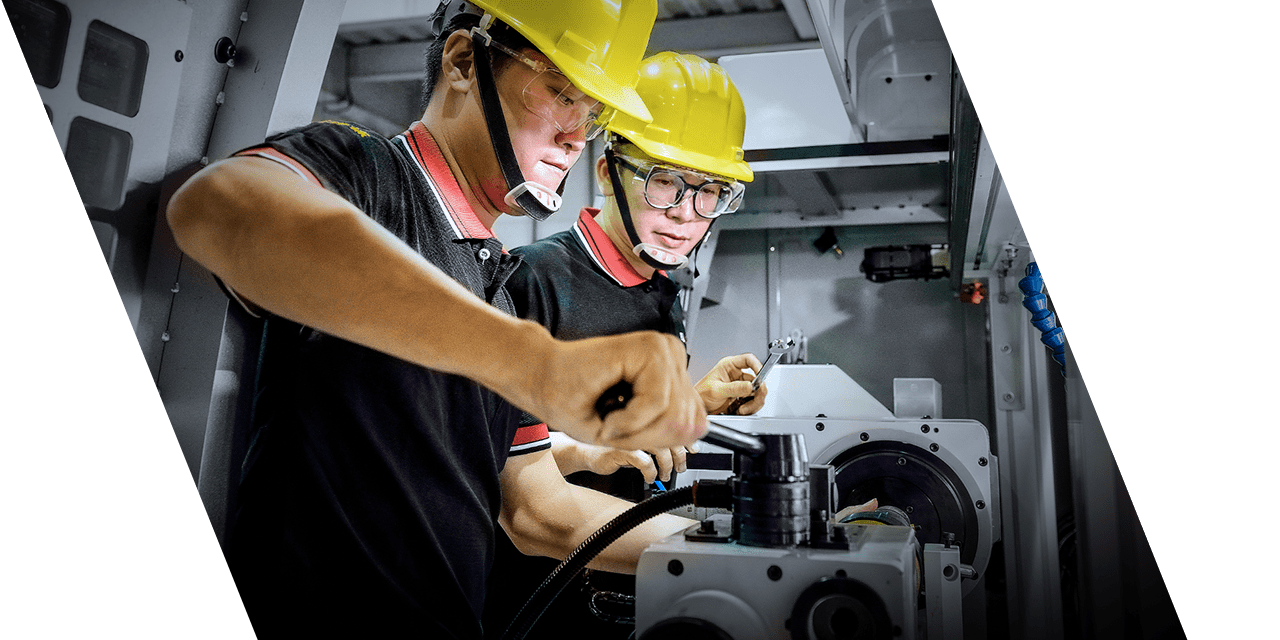

Centerless Grinders CNC Series - alloy bearing type spindle FCL-20 is a product with excellent performance. Grinding accuracy is very important for many industries. The spindle of this series adopts high-quality alloy bearings to ensure stable and high-accuracy operation. At the same time, the one-V-one-flat structure of the lower slide further improves the feeding accuracy of the grinder. The controller adopts CNC numerical control feed, with graphic man-machine interface, which makes the operation more flexible and efficient.

As a professional Centerless Grinding Machines manufacturer, we are committed to providing high-quality products and perfect technical support. We know that grinding accuracy is very important to the needs of customers and the competitiveness of the industry, so we continue to strive to improve our product performance and technical level. When you choose the FCL-20 Centerless Grinder, you can rely on its high-accurate grinding capabilities to deliver excellent results for your machining jobs.