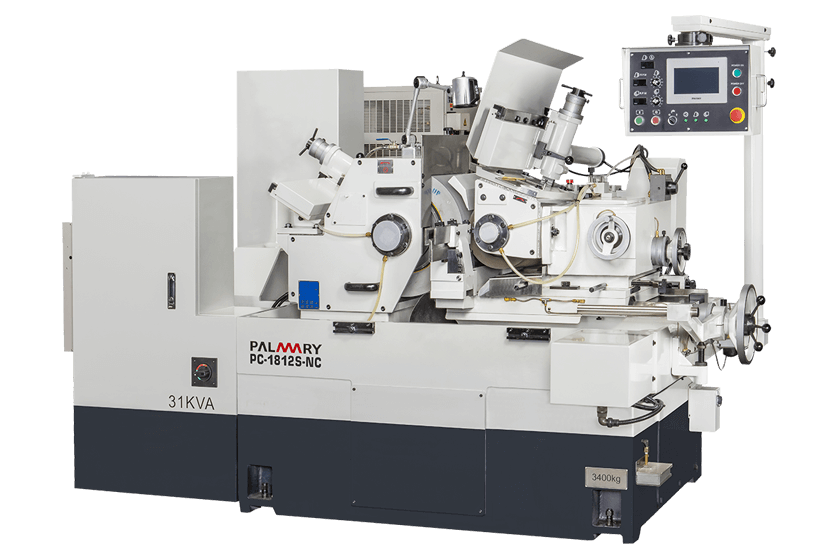

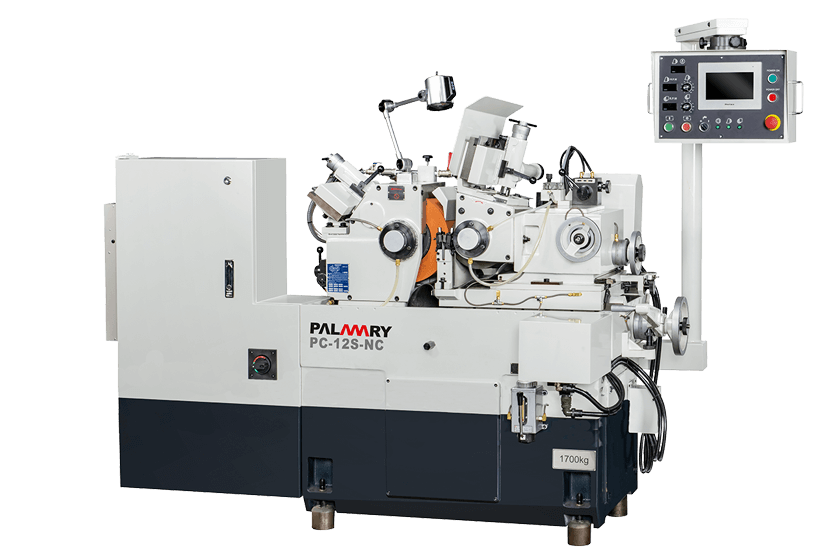

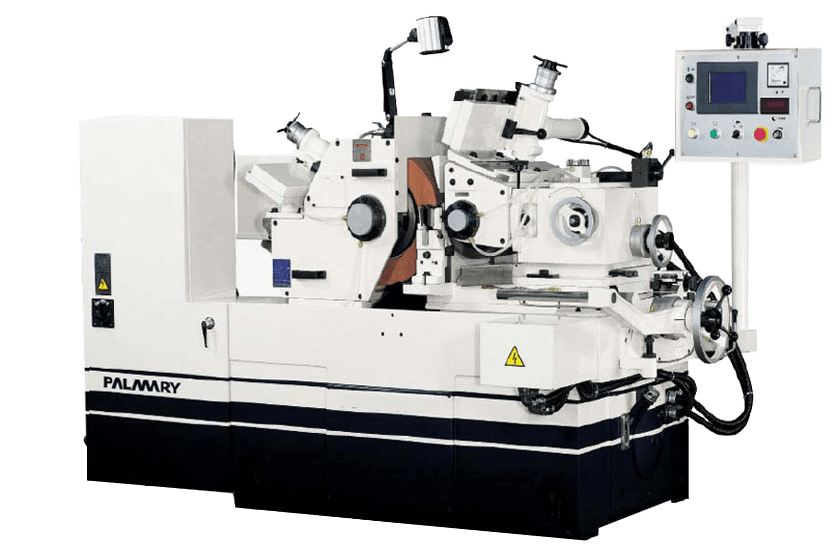

PC-NC

Series

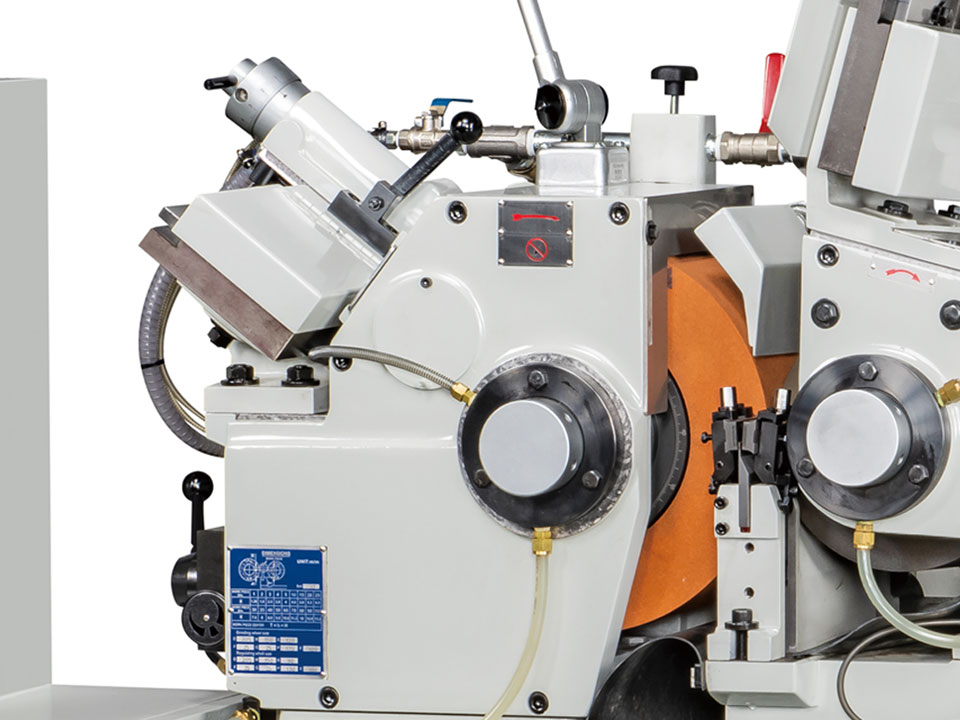

Dia. Ø1~80

Standard grinding range (mm)

Ø455 x 205~305 x Ø228.6

Grinding wheel size (mm)

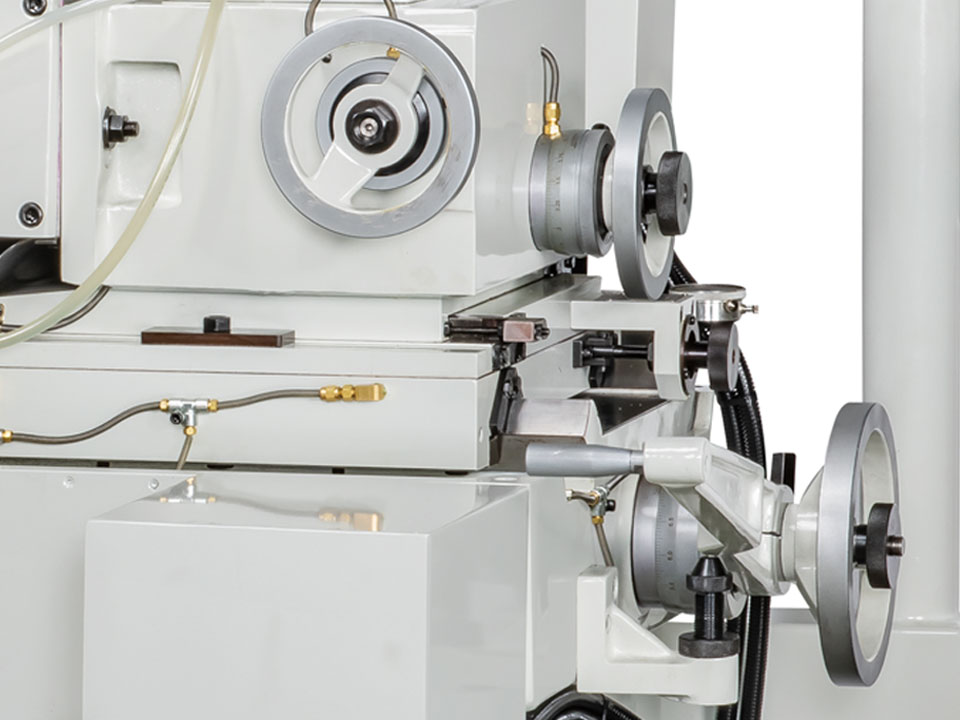

Ø255 x 205~305 x Ø111.2

Regulating wheel size (mm)

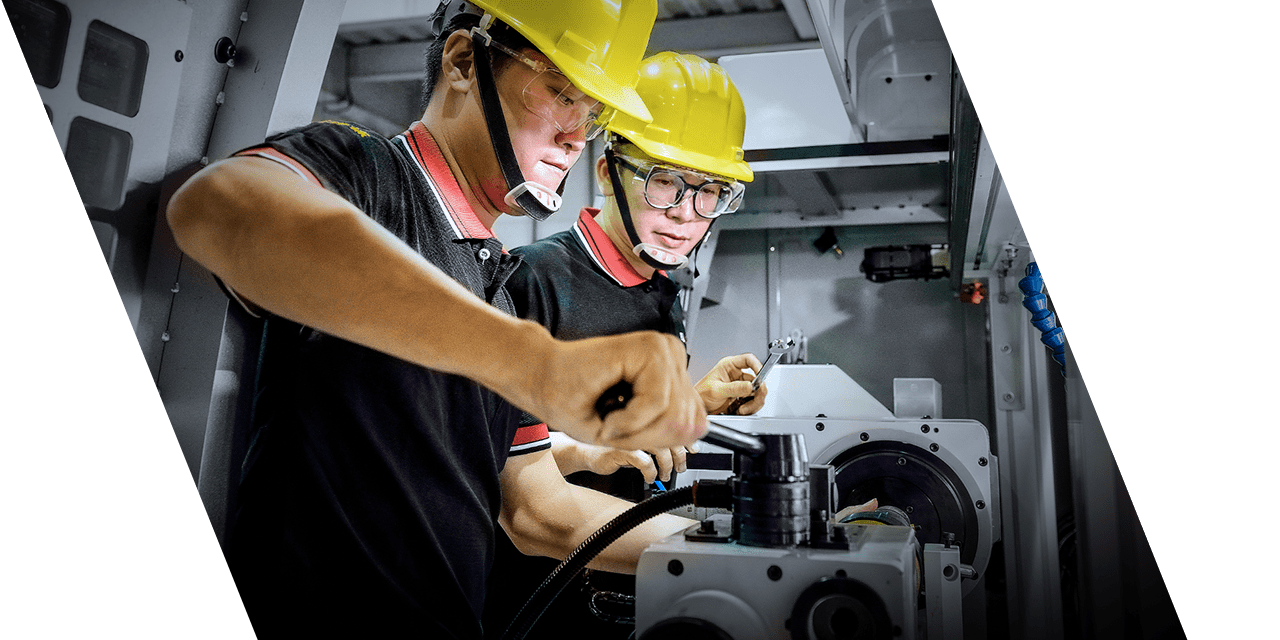

Compared with the traditional standard manual machine, the Centerless Grinder PC-18S-NC adopts a servo motor to drive the regulating wheel and the lower slide feed. With a conversational screen, let users have more convenient operability.

Using the PC-18S-NC Centerless Grinder, the operator can choose the most suitable grinding method and parameters according to the workpiece requirements, such as through-feed grinding or in-feed grinding, to process various workpieces.

Palmary continue to innovate in Centerless Grinding Technology. PC-18S-NC Centerless Grinder, as part of its product line, demonstrates advanced grinding capabilities and operability and meets the needs of high-accuracy grinding.