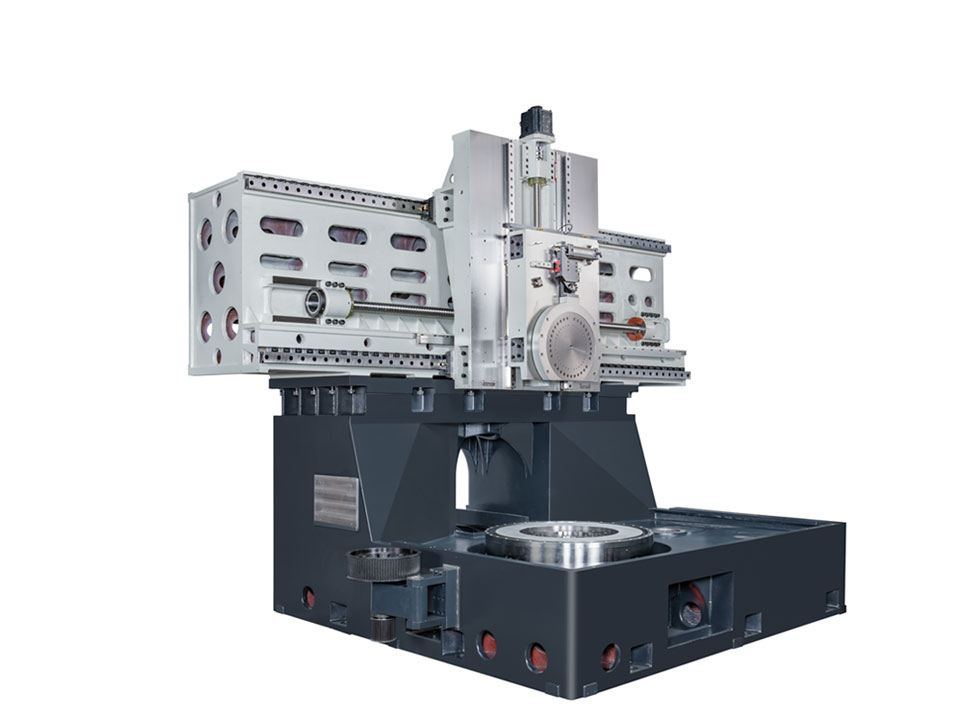

VIG

CNC Series

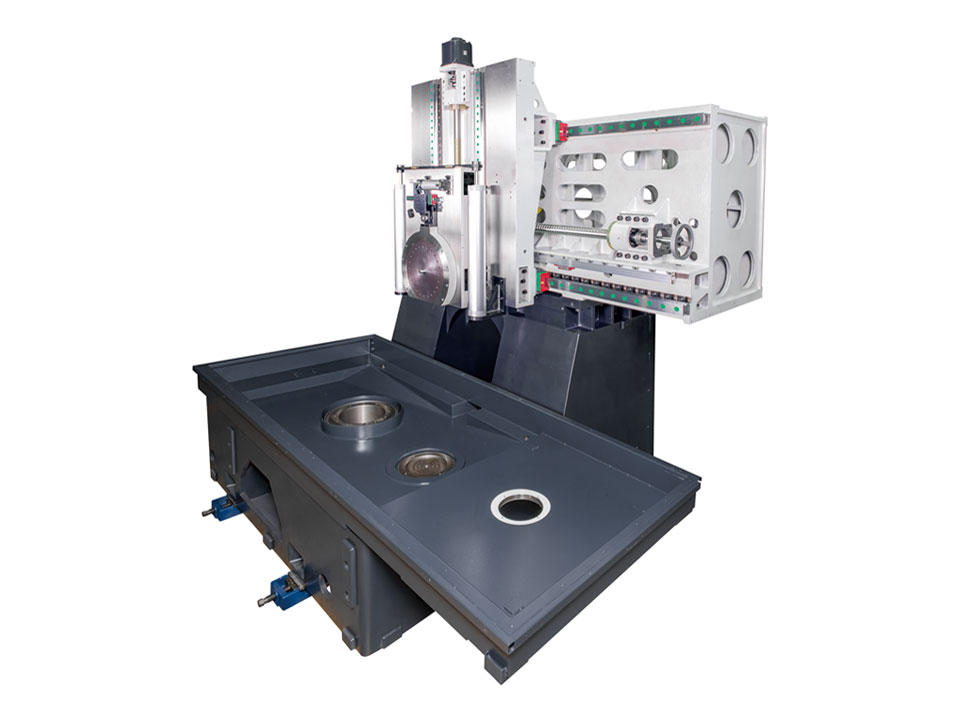

Ø550 / 850 / 1250 mm

Work table size (face plate)

410 / 500 / 500 mm

Max. workpiece length

500 / 1000 / 5000 kgs

Max. workpiece load

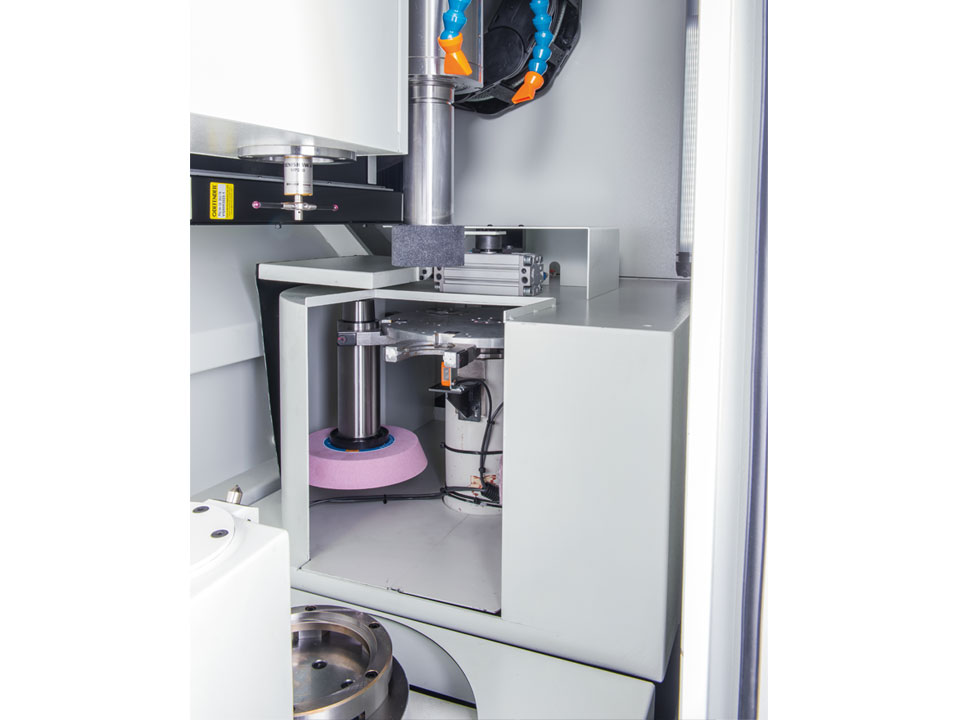

Our CNC Vertical Grinding Machines have excellent machining capabilities and accuracy. The X and Y axes adopt cross roller type linear guideways, which have extra heavy loading capacity. The machine base adopts honeycomb tubular and cross guideway structure providing a stable foundation. In terms of thermal countermeasures, we have increased the isolation area between the processing area and the machine base to reduce thermal deformation and prevent dirt from entering the machine base. At the same time, the equipment is also equipped with an ATC automatic tool change system to achieve efficient tool change.

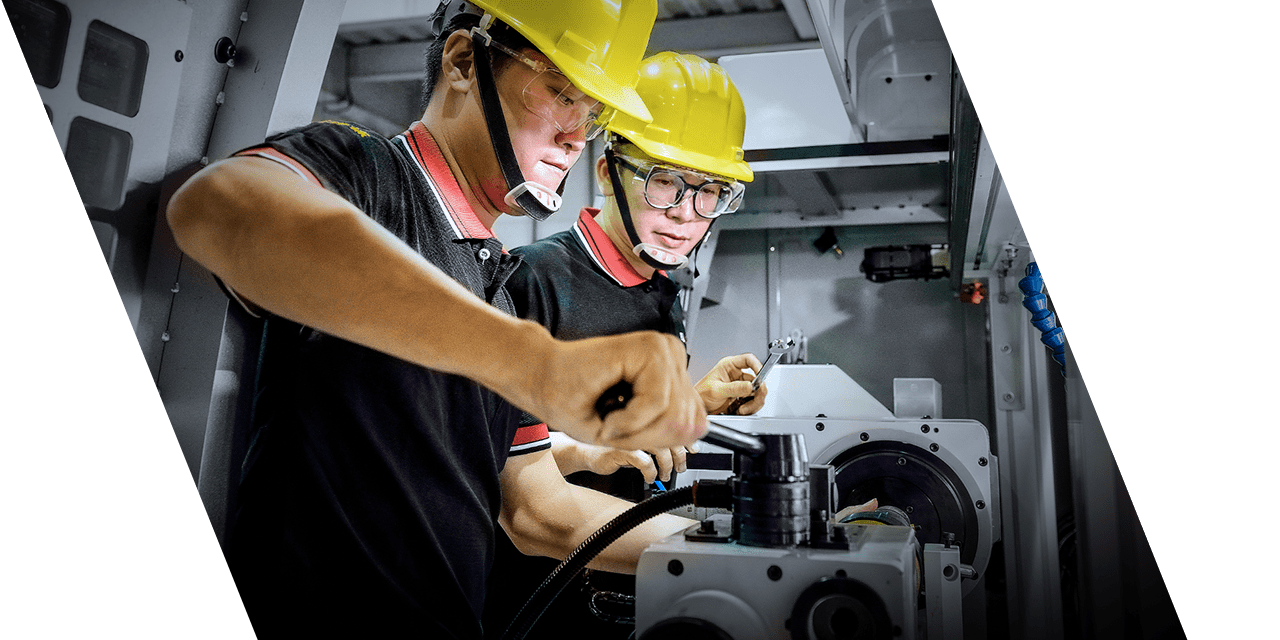

CNC Vertical Grinding Machines are widely used in various industries, including automotive, aerospace, mold making and precision mechanical machining. As a manufacturer of Vertical Grinding Machines, we provide various specifications and configurations to meet different customers’ needs. We are committed to providing high-quality equipment and customized solutions to ensure that customers can obtain efficient and accurate processing results. Our Vertical Grinding Machines can handle a variety of machining needs, whether it is large-scale production or small batch grinding.