OIG

CNC Series

Ø20 mm

Internal grinding range

40 mm

Max. workpiece length

70 / 140 mm

Max. table traverse ( X / Z )

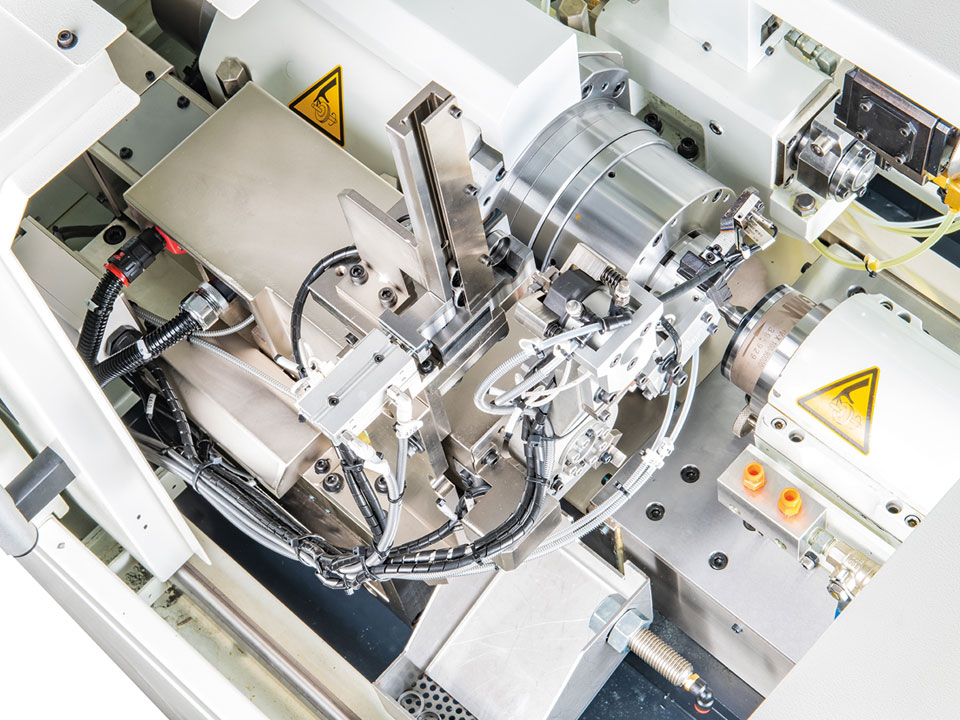

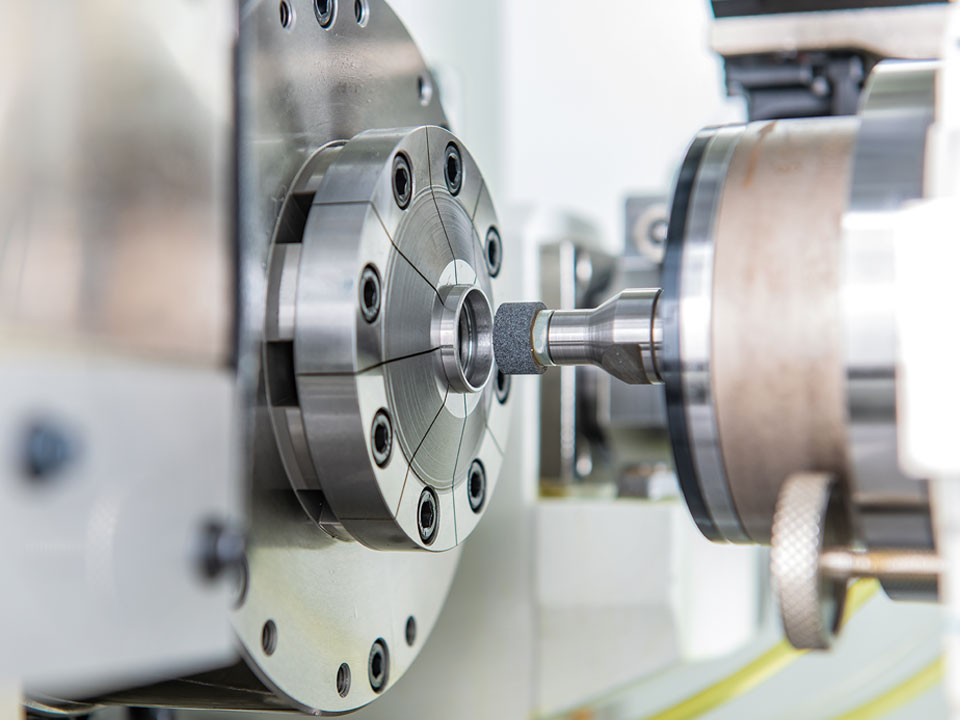

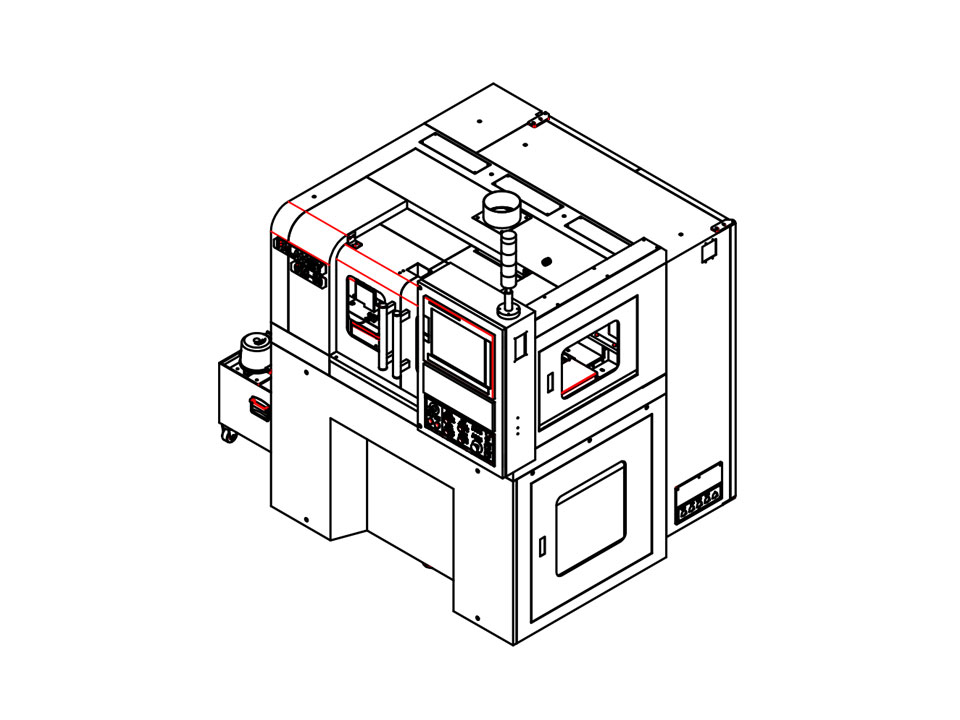

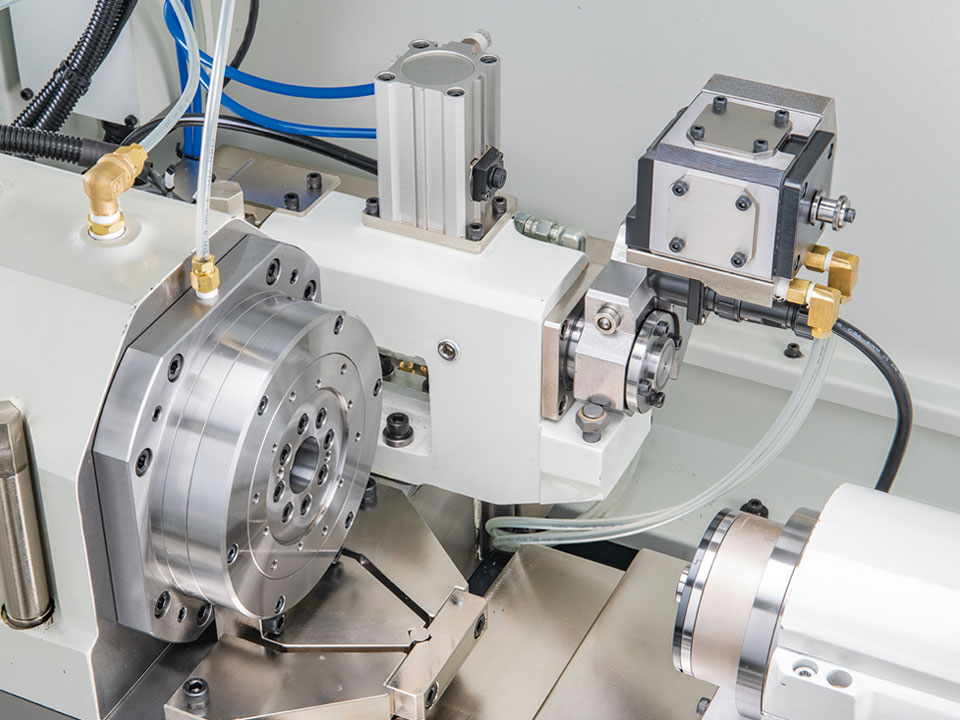

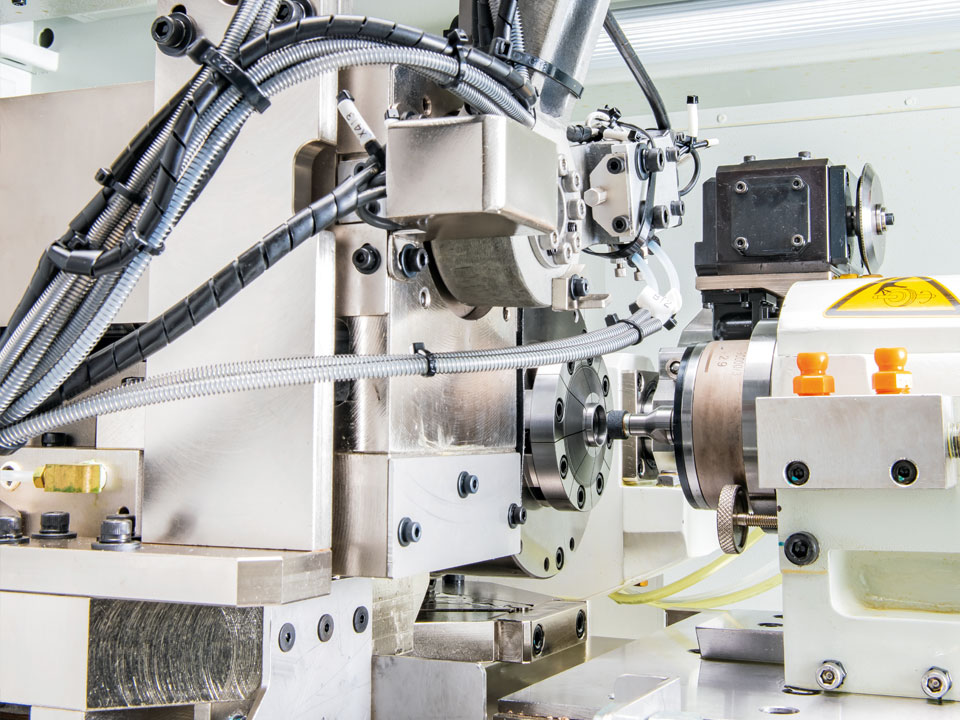

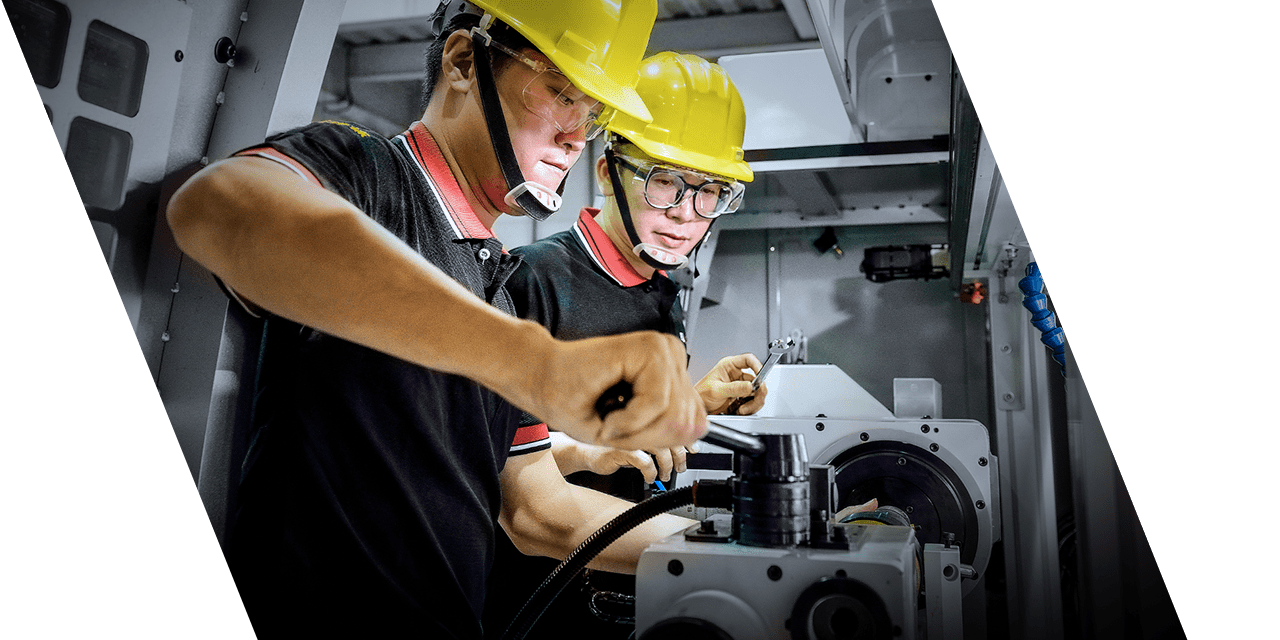

The Internal Grinding Machine OIG-50 adopts the artificial mineral machine body, which reduces the large change caused by temperature rise, improves the stability of the machine, and can perform higher-accuracy processing. The size of the machine tool is only equivalent to the size of B1 paper, which reduces the floor occupation of the machine, and can be matched with the automatic design on the machine to improve the land utilization rate of the customer's workshop. Both the grinding wheel spindle and the work head spindle adopt the built-in spindles with high-precision bearings, which can meet the needs of high-accurate grinding.

This high-speed grinding machine has a wide range of applications, especially for industries that require high-accuracy grinding. It plays an important role in the fields of high-precision mold manufacturing, components, and nozzle parts for the automobile and motorcycle industry.