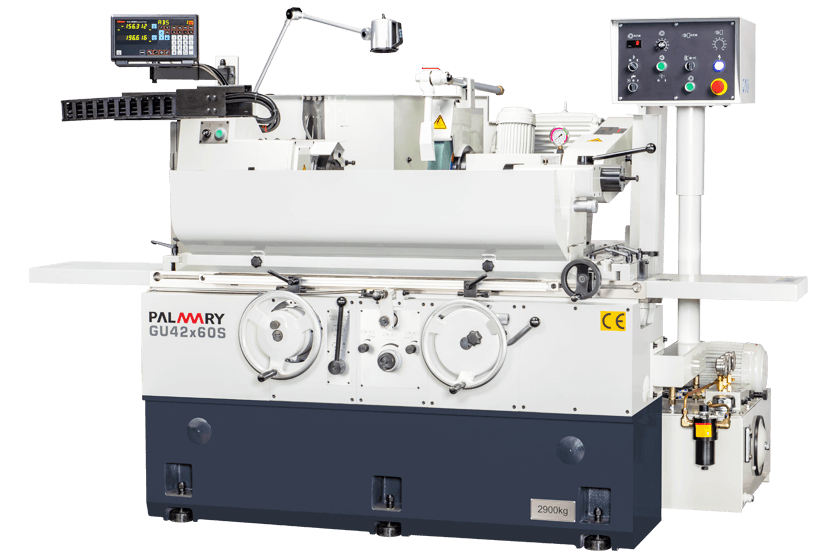

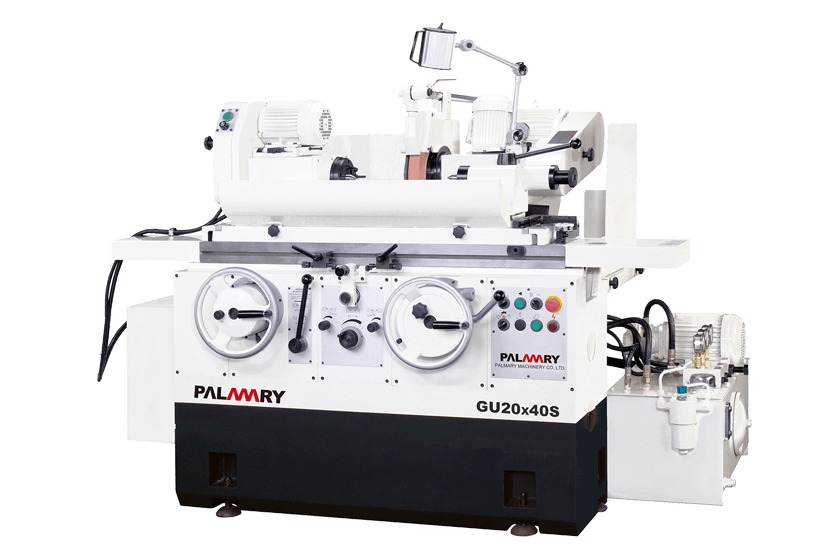

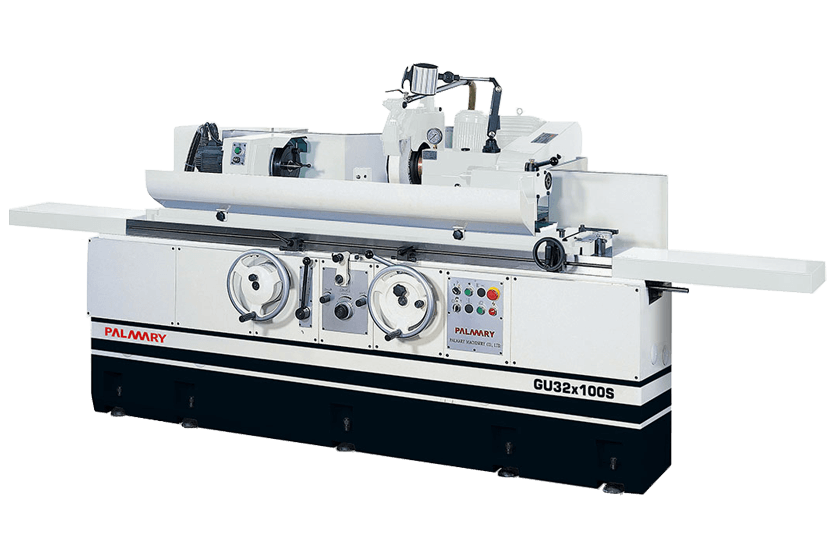

GU-S

Manual Servomotor

600 / 1000 mm 1500 / 2000 mm

Distance between centers

Ø420 mm

Swivel over table

Ø400 mm

Max. external grinding dia.

PALMARY high precision cylindrical grinders are unmatched in structural rigidity and stability, grinding accuracy and operational convenience. Each machine provides maximum operational flexibility thereby allowing for various grinding operations. You will get extra value when putting a PALMARY cylindrical grinder on your production line.