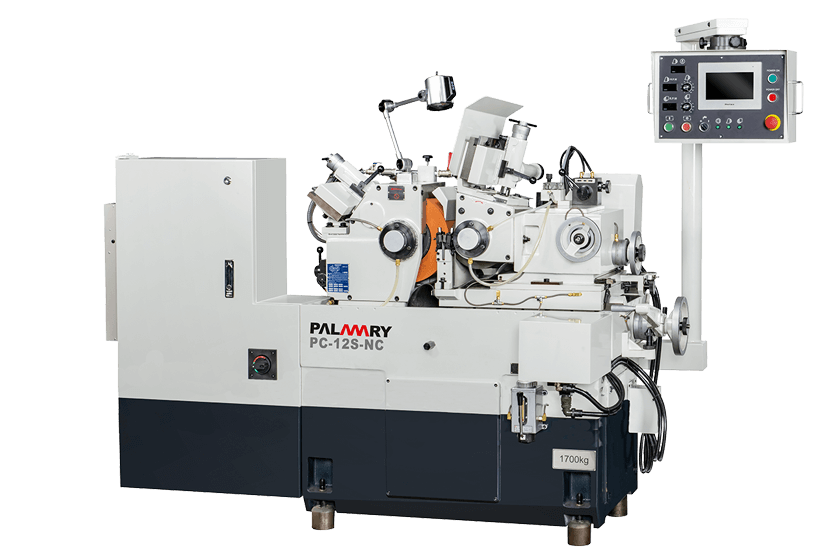

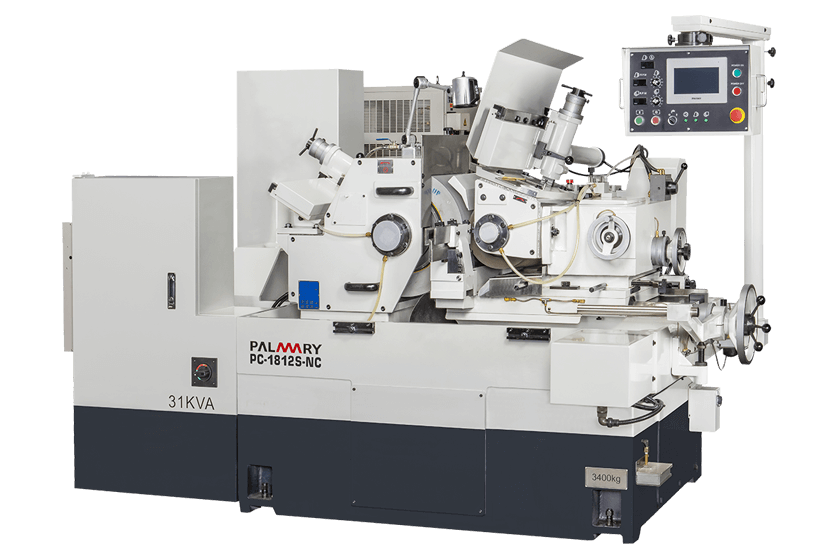

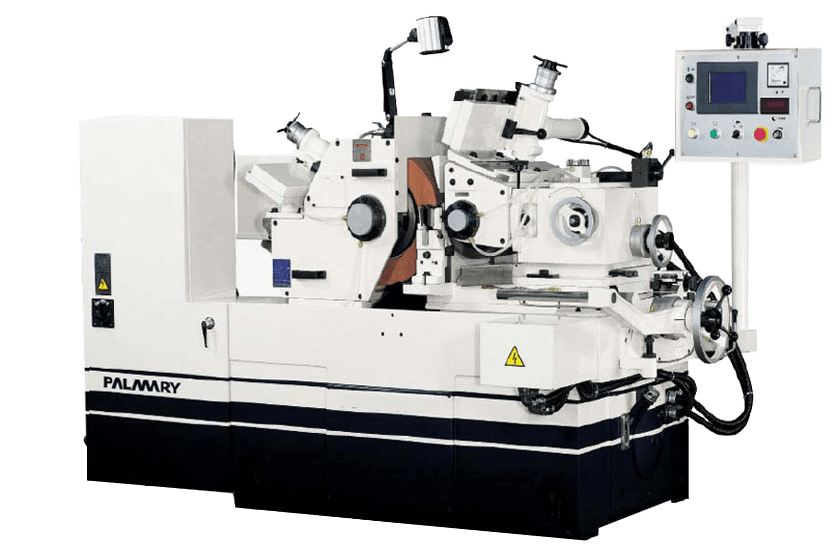

PC-NC

Series

Dia. Ø1~40

Standard grinding range (mm)

Ø305 x 150 x Ø120

Grinding wheel size (mm)

Ø205 x 150 x Ø90

Regulating wheel size (mm)

If you are serious about grinding accuracy and efficiency, the centerless grinders from PALMARY will meet your stringent challenges. The NC-controlled model is quality constructed throughout for delivering the operational performance that you expect.

The machine structure is manufactured from high-quality Meehanite cast iron, heat treated and stress relieved before machining, to make sure the high rigidity.